There is an ongoing battle between cancer cells and p53, the protein known as “the guardian of the genome,” and a study conducted at the University of Trento has identified a number of factors that influence the outcome of this battle and therefore the effectiveness of cancer treatments.

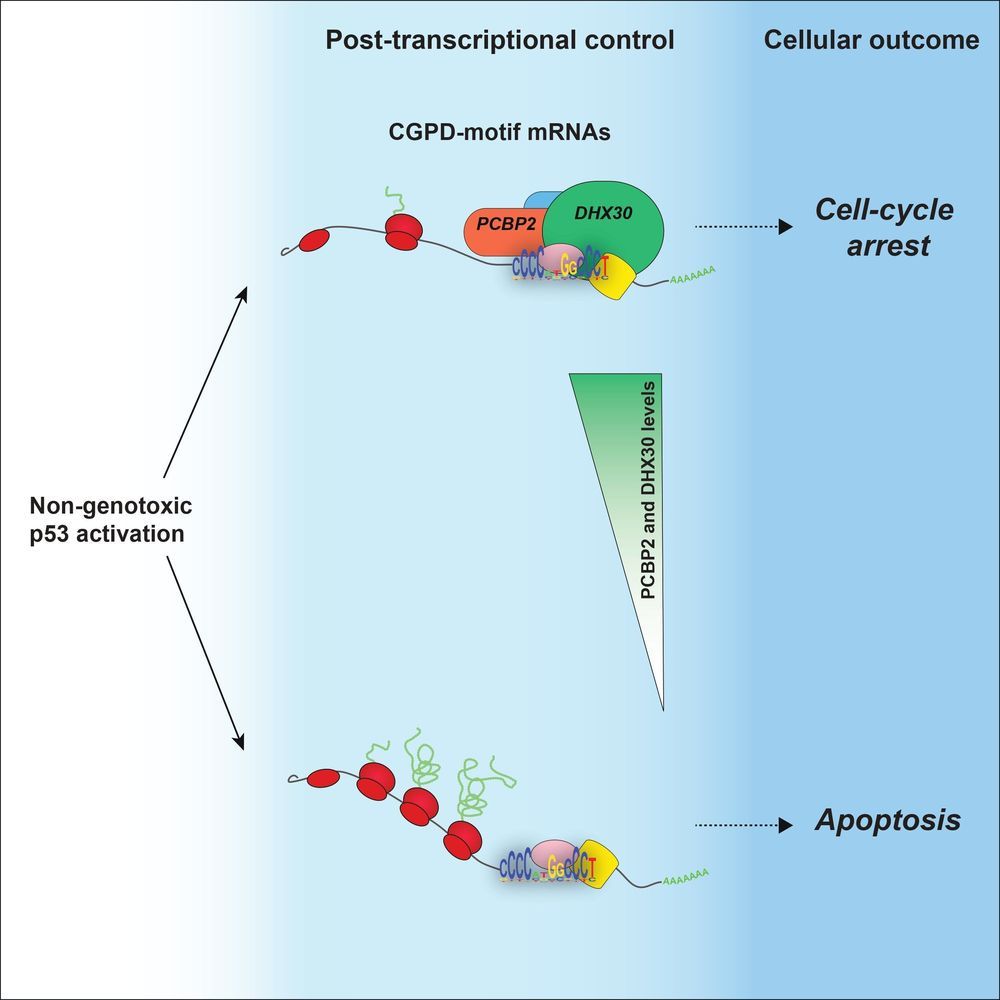

Scientists explore two therapeutic cancer treatment scenarios: In one scenario, cancer cells stop proliferating; in the other, their death rate increases. Both of these outcomes are regulated the protein p53. Based on the new findings, a specific factor, a protein known as DHX30, determines how p53 can lead cancer cells to their death. That is the conclusion reached by a team of researchers of the University of Trento, who focused on a new molecular mechanism that works like a switch.

Erik Dassi, member of the research team, said, “When cancer cells are treated with a certain drug, it is the action of this switch (DHX30) that makes them to go toward cell death and not in the direction of cell cycle arrest.”