File stores synthesis and characterisation data, much like files for crystal structures

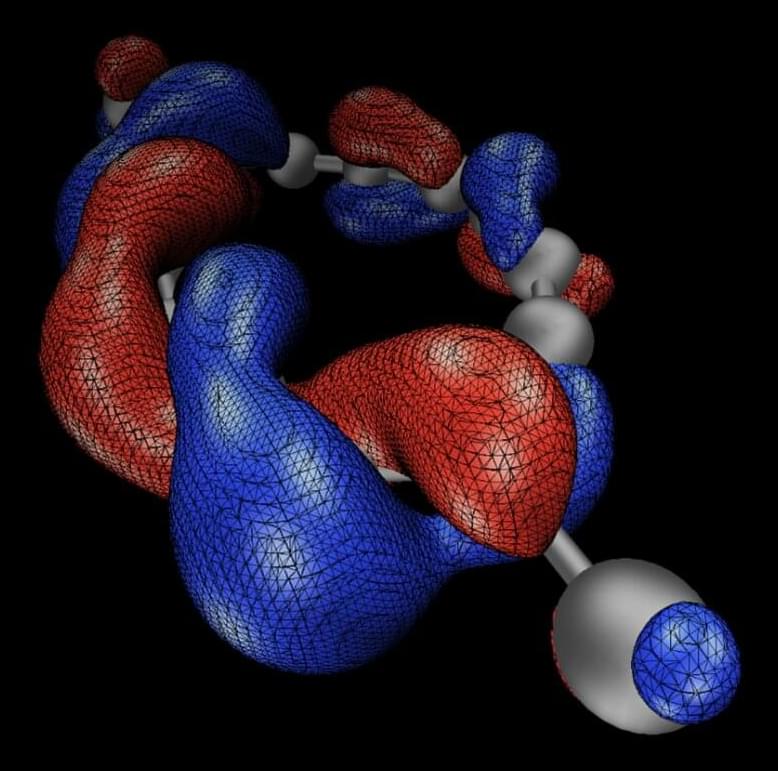

An international team of scientists from IBM, The University of Manchester, Oxford University, ETH Zurich, EPFL and the University of Regensburg have created and characterized a molecule unlike any previously known—one whose electrons travel through its structure in a corkscrew-like pattern that fundamentally alters its chemical behavior. The work appears in Science.

This is the first experimental observation of a half-Möbius electronic topology in a single molecule. To the scientists’ knowledge, a molecule with such topology has never before been synthesized, observed, or even formally predicted.

Understanding this molecule’s behavior at the electronic structure level required something equally fundamental: a high-fidelity quantum computing simulation. The discovery advances science on two fronts. For chemistry, it demonstrates that electronic topology—the property governing how electrons move through a molecule—can be deliberately engineered, not merely found in nature.

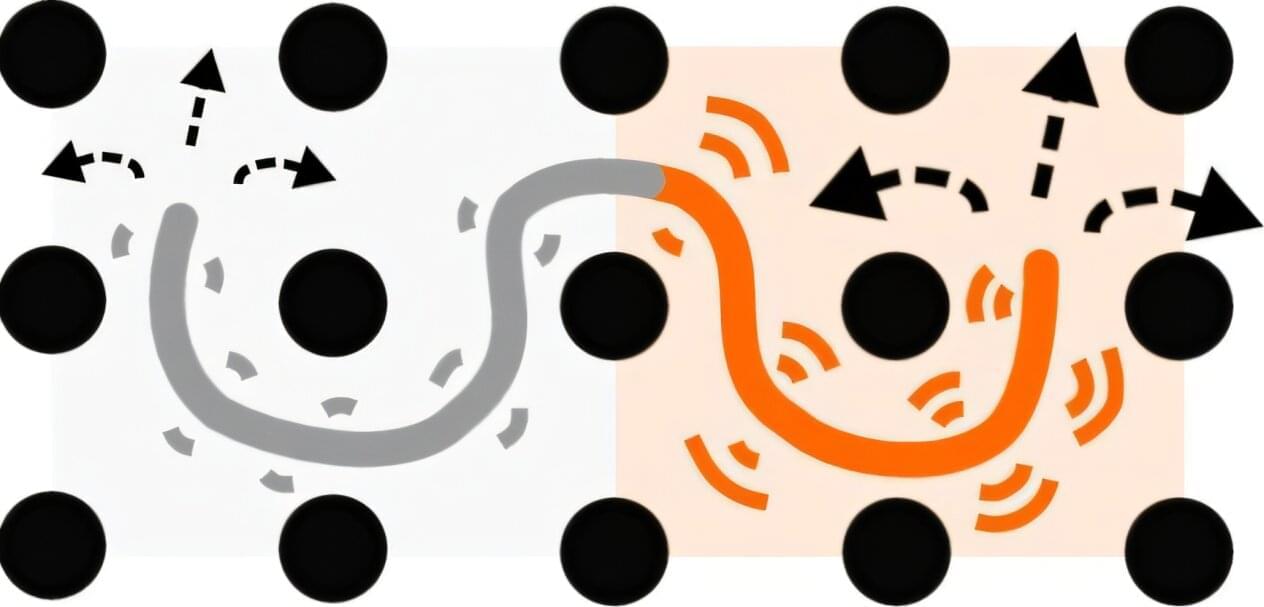

Researchers at the University of Vienna have uncovered a surprising phenomenon: polymer chains with segments that simply fluctuate at different intensities can spontaneously develop directional, persistent motion when densely packed—even though nothing in the system points them in any particular direction. This “entropic tug of war,” driven by fundamental physical constraints, could help explain how DNA organizes and moves inside living cells and may lead to new materials. The study is published in Physical Review X.

“Think of a chain threaded through a dense forest of trees, which represent obstacles posed by the other chains in the system. One end of the chain is being shaken much more vigorously than the other,” explains lead author Jan Smrek from the Faculty of Physics at the University of Vienna. “You might expect it to just wiggle randomly in place. But we found that because the chain has to find its way by going in-between the trees, the difference in shaking intensity creates an imbalance that actually propels the entire chain forward through the forest.”

This analogy can be conferred to a polymer, a large molecule consisting of many units linked together in a long chain, such as DNA. The Viennese research team—Adam Höfler, Iurii Chubak, Christos Likos and Jan Smrek—used computer simulations and analytical theory to show that this directed motion arises purely from topological constraints. When polymer chains are entangled and cannot pass through each other, segments with stronger fluctuations generate larger entropic forces. This creates an imbalance that pushes the entire chain forward along its own contour, with the stronger fluctuating part acting as the “head of the snake” moving through the forest of obstacles.

Caltech scientists have developed a method that detects tiny, imperceptible movements at the surface of objects to reveal details about what lies beneath. By analyzing the physics of waves traveling across the surface of an object—whether that be a manufactured product or the human body—the new technique can determine both the stiffness and thickness of the underlying material or tissue. This lays the groundwork for the project’s ultimate goal of enabling inexpensive, at-home health monitoring using little more than a smartphone camera.

“There is information scattered all around us in plain sight that we just haven’t learned to tap into. Our work is trying to leverage that information to recover material properties from inside objects by studying tiny movements on the surface,” says Katie L. Bouman, professor of computing and mathematical sciences, electrical engineering, and astronomy at Caltech and both a Rosenberg Scholar and a Heritage Medical Research Institute (HMRI) Investigator.

Bouman and her colleagues from Caltech presented the technique, called visual surface wave elastography, and its medical applications in a paper presented at the International Conference on Computer Vision in Honolulu last fall. The lead authors are Alexander C. Ogren, Ph.D., and Berthy T. Feng, Ph.D., who completed the work while at Caltech.

Electrical engineers at Duke University have demonstrated the fastest pyroelectric photodetector to date, which works by absorbing heat generated by incoming light. Capable of capturing light from the entire electromagnetic spectrum, the ultrathin device requires no external power, operates at room temperature and can be readily integrated into on-chip applications.

The advance could form the basis of a new class of multispectral cameras capable of impacting a wide range of fields such as skin cancer detection, food safety inspection and large-scale agriculture.

The results appear in Advanced Functional Materials.

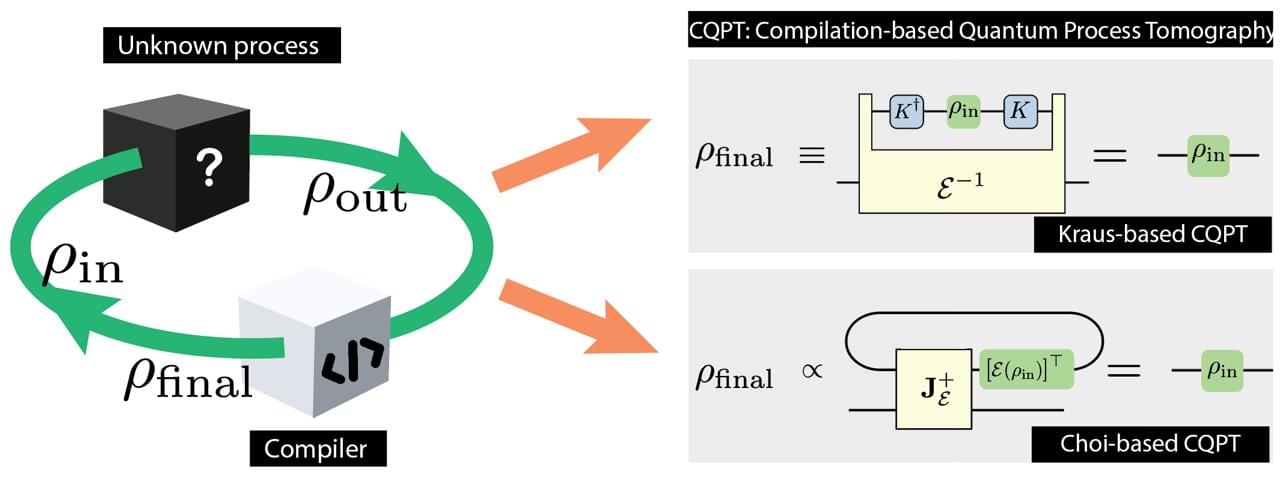

Quantum computers work by applying quantum operations, such as quantum gates, to delicate quantum states. Ideally, quantum computers can solve complex equations at staggeringly fast speeds that vastly outpace regular computers. In real hardware, the operations of quantum computers often deviate from the ideal behavior because of device imperfections and unwanted noise from the environment. To build reliable quantum machines, researchers need a way to accurately determine what a quantum device is actually doing.

Quantum process tomography (QPT) is a standard method for this. However, traditional QPT becomes very costly as the system grows, because the number of required measurements and calculations increases rapidly with the number of qubits.

To address this challenge, a research team from Tohoku University, the Nara Institute of Science and Technology (NAIST), and the University of Information Technology (Vietnam National University, Ho Chi Minh City) has introduced a new framework called compilation-based quantum process tomography (CQPT). The work is published in Advanced Quantum Technologies.

Researchers at the University of Innsbruck, together with partners from Sydney and Waterloo, have presented a new diagnostic method for quantum computers. It makes errors in individual quantum bits visible during logical calculation and evaluates them. The new method was demonstrated on an ion trap quantum processor in Innsbruck. It can be used to identify critical error sources—a key to developing more robust, fault-tolerant quantum processors.

In Physical Review X, the researchers present a scalable method that can be used to reliably characterize logical quantum operations at the level of the underlying quantum bits. Cycle error reconstruction identifies which physical errors influence the performance of logically encoded gates.

“With cycle error reconstruction, we can quantitatively capture the error structure and clearly distinguish between correctable and uncorrectable contributions,” says first author Robert Freund from the Department of Experimental Physics.

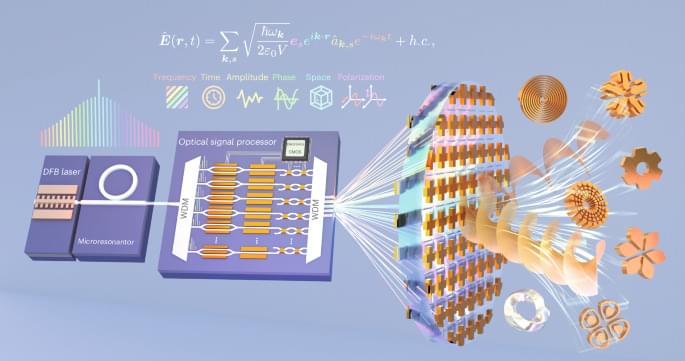

Using a chip-based microcomb, full dimensional control of structured microwaves is demonstrated, including vortex-microwave generation, submicrosecond spatiotemporal mode switching, broadband phase–frequency response tuning and wide-angle two-dimensional beam steering. These capabilities are applied in a structured-microwave-based integrated sensing and communication system.