A study presents battery-free, polymer-based wearable devices that wrap around neurons, allowing for real-time monitoring and modulation of cellular activity. This innovation aims to restore neuronal function in conditions like multiple sclerosis.

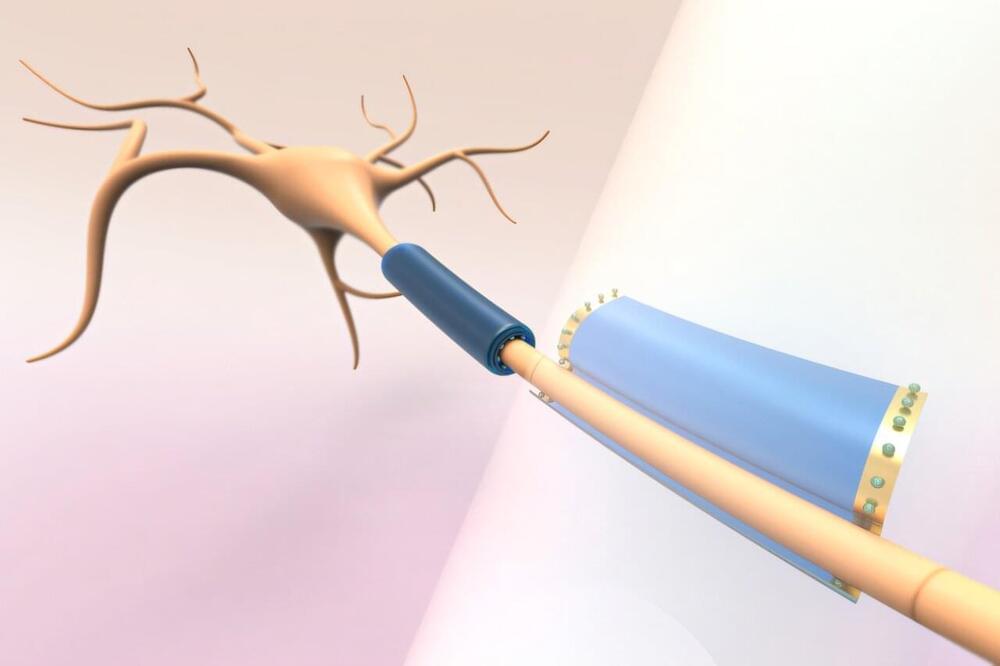

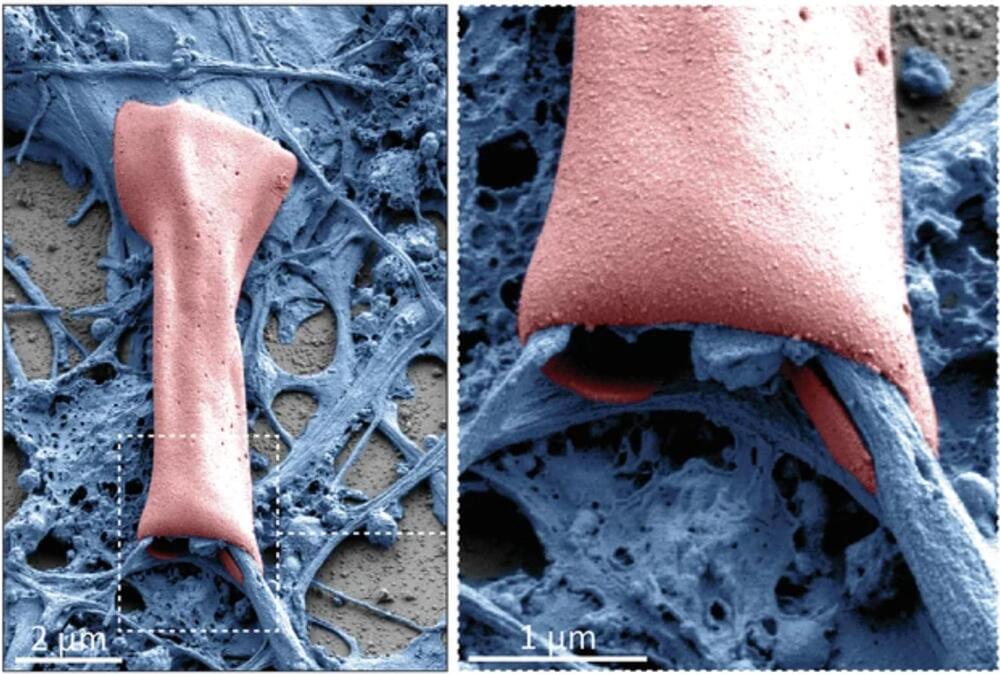

MIT researchers have developed a battery-free, subcellular-sized device made of polymer designed to measure and modulate a neuron’s electrical and metabolic activity. When the device is activated by light, it can gently wrap around the neuron cell’s axons and dendrites without damaging the cells.

Scientists want to inject thousands of these tiny wireless devices into a patient’s central nervous system and then actuate them noninvasively using light. The light would penetrate the tissue and allow precise control of the devices, and thereby restore function in cases of neuronal degradation like multiple sclerosis (MS).

The MIT researchers developed these thin-film devices from a azobenzene, a soft polymer that readily reacts to light. Thin sheets of azobenzene roll into a cylinder when exposed to light, which enables them to wrap around cells. Researchers can control the direction and diameter of the rolling by changing the intensity and polarization of the light, producing a microtube with a diameter smaller than one micrometer.

Researchers develop nanomaterial textiles for wireless power, allowing real-time data transmission without the need for bulky batteries.

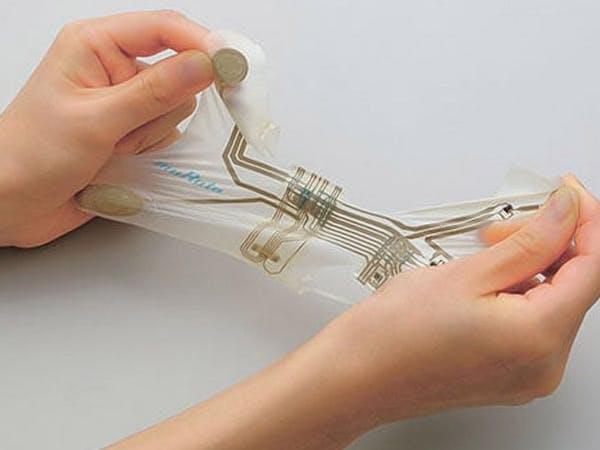

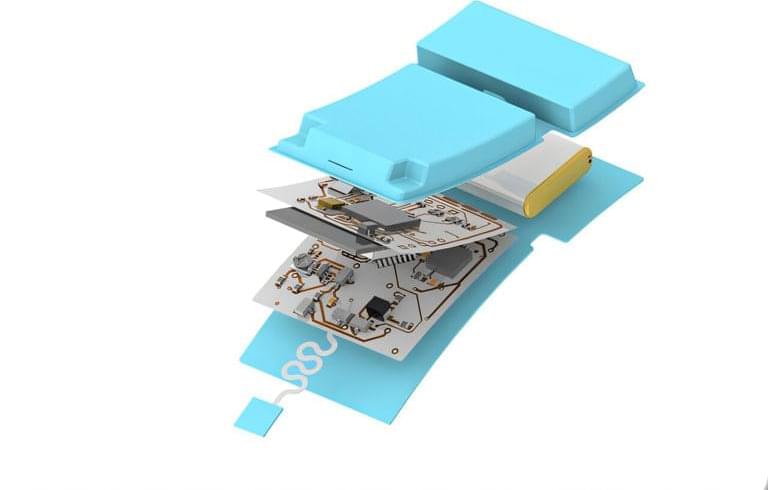

Murata is branching out from its usual ceramic components with the launch of flexible, stretchable electronics — a Stretchable Printed Circuit (SPC) platform it says is ideally positioned for wearable and medical devices.

In recent years, in the medical field, to make more accurate diagnoses, the…

Bendy, soft, stretchy devices target the wearable and medical markets.

Wearable devices like smartwatches and fitness trackers interact with parts of our bodies to measure and learn from internal processes, such as our heart rate or sleep stages.

Now, MIT researchers have developed wearable devices that may be able to perform similar functions for individual cells inside the body.

These battery-free, subcellular-sized devices, made of a soft polymer, are designed to gently wrap around different parts of neurons, such as axons and dendrites, without damaging the cells, upon wireless actuation with light. By snugly wrapping neuronal processes, they could be used to measure or modulate a neuron’s electrical and metabolic activity at a subcellular level.

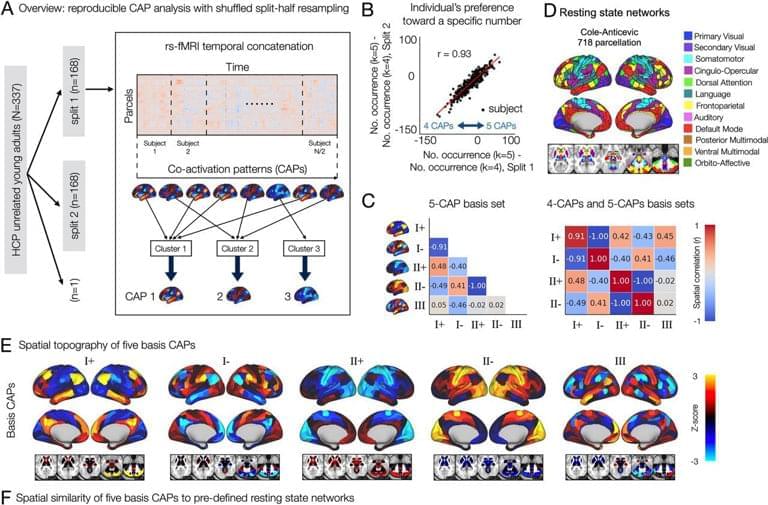

A key challenge in the effort to link brain activity with behavior is that brain activity, measured by functional magnetic resonance imaging (fMRI), for instance, is extraordinarily complex. That complexity can make it difficult to find recurring activity patterns across different people or within individuals.

In a new study, Yale researchers were able to take fMRI data, reduce its complexity, and in doing so, uncover stable patterns of activity shared across more than 300 different people. The findings, researchers say, are a promising step forward in uncovering biomarkers for psychiatric disorders.

The study was published Sept. 24 in the journal PLOS Biology.

This is clearly aimed at Wearable AI such as the Ray-Ban Meta Wayfarers and other similar devices.

I was wondering how large of a language model can you fit in a pair of sunglasses?

Meta AI researchers have unveiled MobileLLM, a new approach to creating efficient language models designed for…

Key innovations in Meta’s MobileLLM include prioritizing model depth over width, implementing embedding sharing and grouped-query attention and utilizing a novel immediate block-wise weight-sharing technique.

While using the Meta AI chatbot on WhatsApp it answered my query with some great advice.

It almost felt like I had some support from a good friend.

I was kind of taken aback by the answer. Since I purchased the Ray-Ban \ Meta Wayfarers I have jokingly told people that I am wearing a large language model on my face. I came to find out that information is incorrect.

Meta AI responded, “That’s a cool device! Unfortunately, I’m not compatible with the Ray-Ban Meta smart glasses (yet!). I exist solely as a text-based AI assistant, so you can’t talk to me directly through the glasses.”

It continued, “However, you can use the glasses to access a device with a keyboard or voice-to-text functionality, and then interact with me through text. Keep in mind that I’m constantly evolving, so who knows? Maybe future updates will enable voice interactions or compatibility with devices like your Meta glasses!”

Finding ways to connect the human body to technology could have broad applications in health and entertainment. A new “electric plastic” could make self-powered wearables, real-time neural interfaces, and medical implants that merge with our bodies a reality.

While there has been significant progress in the development of wearable and implantable technology in recent years, most electronic materials are hard, rigid, and feature toxic metals. A variety of approaches for creating “soft electronics” has emerged, but finding ones that are durable, power-efficient, and easy to manufacture is a significant challenge.

Organic ferroelectric materials are promising because they exhibit spontaneous polarization, which means they have a stable electric field pointing in a particular direction. This polarization can be flipped by applying an external electrical field, allowing them to function like a bit in a conventional computer.