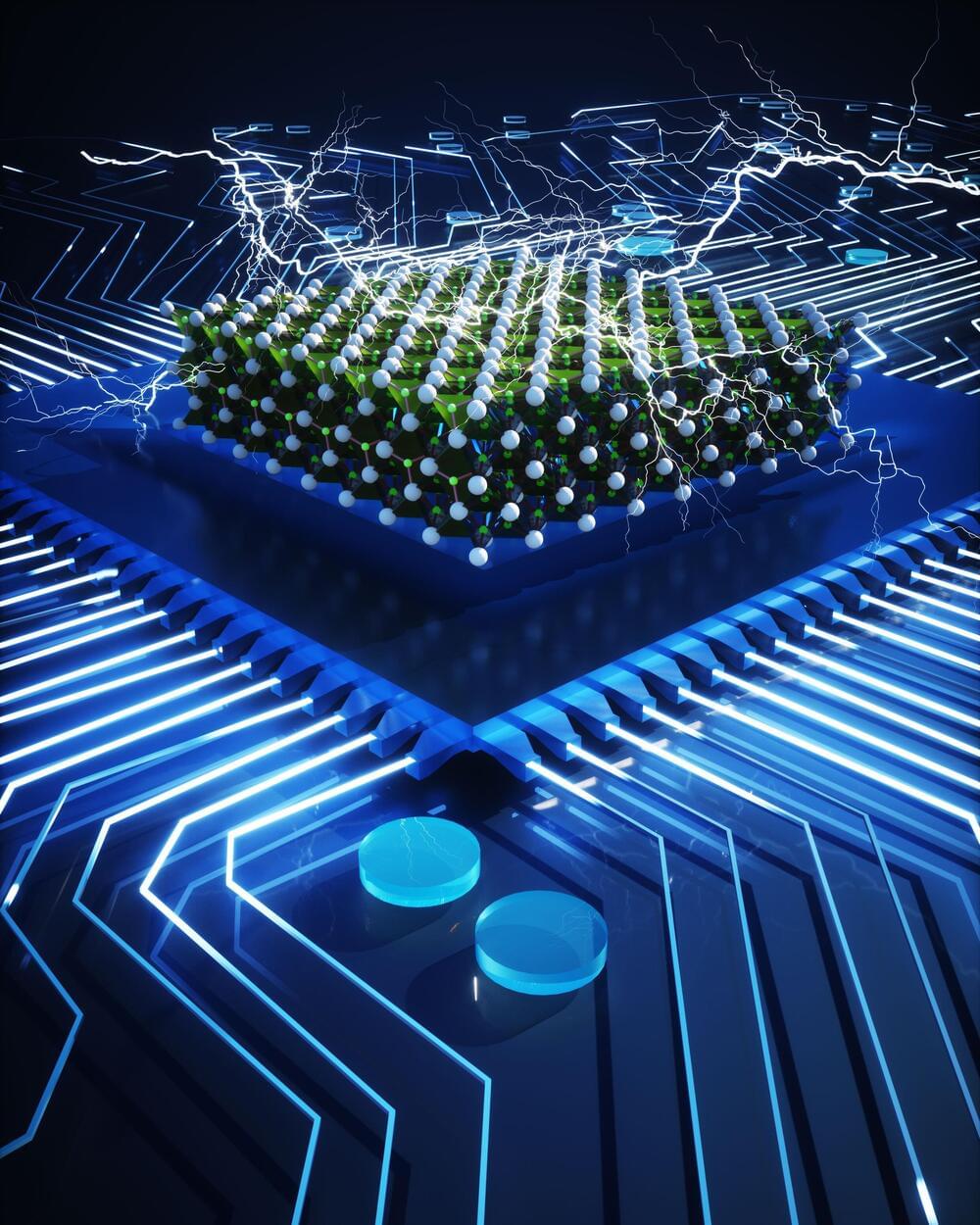

Computers may be growing smaller and more powerful, but they require a great deal of energy to operate. The total amount of energy the U.S. dedicates to computing has risen dramatically over the last decade and is quickly approaching that of other major sectors, like transportation.

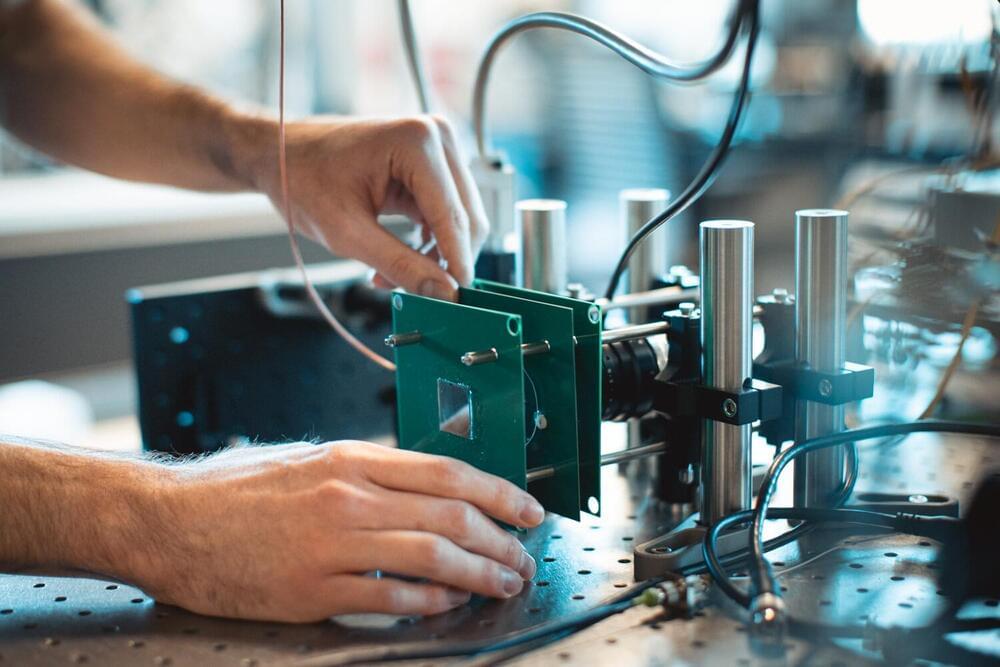

In a study published online this week the journal Nature, University of California, Berkeley, engineers describe a major breakthrough in the design of a component of transistors—the tiny electrical switches that form the building blocks of computers—that could significantly reduce their energy consumption without sacrificing speed, size or performance. The component, called the gate oxide, plays a key role in switching the transistor on and off.

“We have been able to show that our gate-oxide technology is better than commercially available transistors: What the trillion-dollar semiconductor industry can do today—we can essentially beat them,” said study senior author Sayeef Salahuddin, the TSMC Distinguished professor of Electrical Engineering and Computer Sciences at UC Berkeley.