Tesla recorded $500M+ in gross profit from its Energy and Services (Supercharging) segments in Q3 2023. Elon Musk noted how strong energy gross margins were on the call, and insinuated strength in these businesses will continue. I think this is a super exciting development for Tesla investors as the company can smooth out cyclicality in it’s automotive business with consistent profits from its Energy and Services.

Category: transportation – Page 127

The first EV with a lithium-free sodium battery hits the road in January

JAC Motors, a Volkswagen-backed Chinese automaker, is set to launch the first mass-produced electric vehicle (EV) with a sodium-ion battery through its new Yiwei brand. Although sodium-ion battery tech has a lower density (and is less mature) than lithium-ion, its lower costs, more abundant supplies and superior cold-weather performance could help accelerate mass EV adoption. CarNewsChina reports that the JAC Yiwei EV hatchback deliveries will begin in January.

Yiwei is a new brand in 2023 for JAC. Volkswagen has a 75 percent stake in (and management control of) JAC and owns 50 percent of JAC’s parent company, Anhui Jianghuai Automobile Group Holdings (JAG). The Chinese government owns the other half of JAG, making for one of the auto industry’s stranger pairings.

The Yiwei EV appears to be a rebranded version of the Sehol E10X hatchback (above), announced earlier this year. CarNewsChina describes the Sehol model as having a 252 km (157 miles) range with a 25 kWh capacity, 120 Wh / kg energy density, 3C to 4C charging, and a HiNa NaCR32140 cell. When JAC revealed the Yiwei brand in May, it said it would drop the Sehol label and rebrand all its vehicles to either JAC or Yiwei, leading us to this week’s EV reveal. JAC hasn’t yet said whether the Yiwei-branded model will keep the E10X moniker.

Tesla Giga Shanghai to release 2024 Model Y refresh

Tesla Giga Shanghai plans to release 2024 Model Y refresh as competition heats up in China.

People familiar with the matter told Bloomberg that Gigafactory Shanghai is already preparing to produce the 2024 refresh Model Y. Mass production on the new Model Y is expected to start by mid-2024.

The new Model Y units will be produced in the new phase of Gigafactory Shanghai. Production in the second phase of Tesla China’s factory will be suspended during New Year’s for upgrades. More updates to the Model Y assembly line will be made after the holidays.

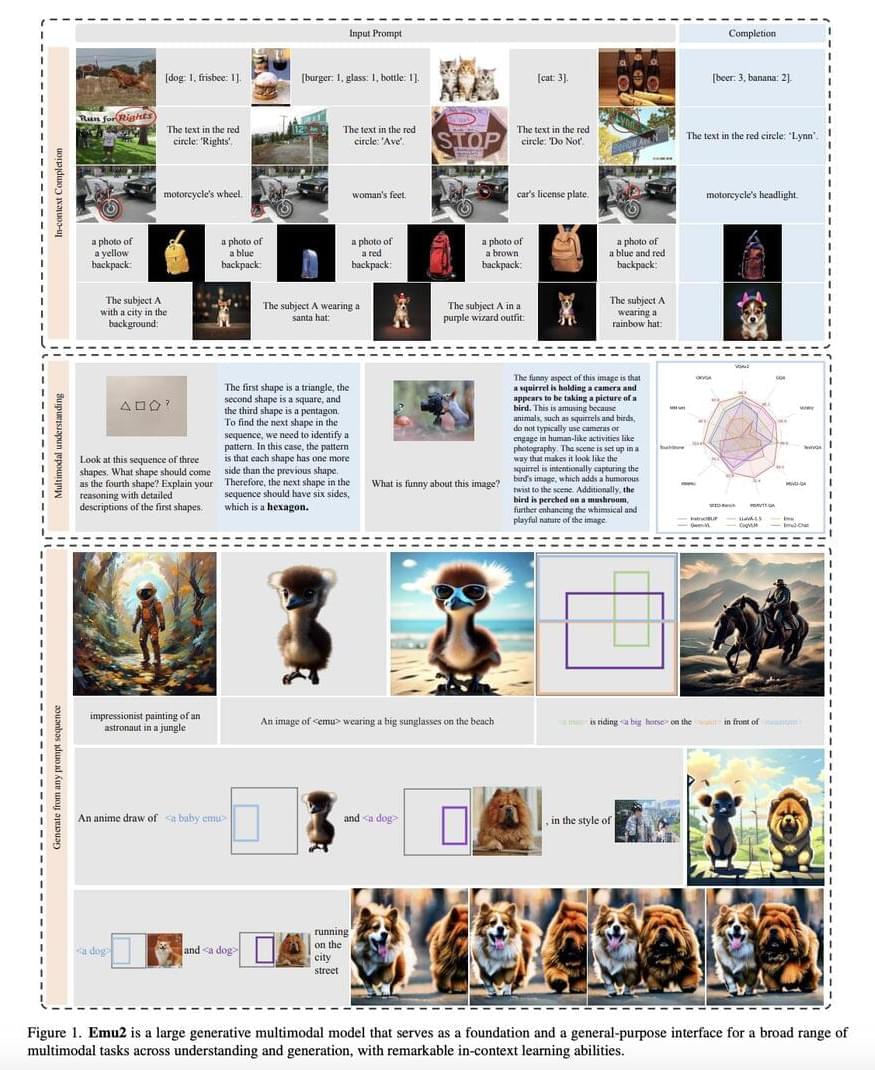

This AI Paper from China Introduces Emu2: A 37 Billion Parameter Multimodal Model Redefining Task Solving and Adaptive Reasoning

Any activity that requires comprehension and production in one or more modalities is considered a multimodal task; these activities can be extremely varied and lengthy. It is challenging to scale previous multimodal systems because they rely heavily on gathering a large supervised training set and developing task-specific architecture, which must be repeated for every new task. In contrast, present multimodal models have not mastered people’s ability to learn new tasks in context, meaning that they can do so with minimal demonstrations or instructions. Generative pretrained language models have recently shown impressive skills in learning from context.

New research by researchers from Beijing Academy of Artificial Intelligence, Tsinghua University, and Peking University introduces Emu2, a 37-billion-parameter model, trained and evaluated on several multimodal tasks. Their findings show that when scaled up, a multimodal generative pretrained model can learn similarly in context and generalize well to new multimodal tasks. The objective of the predict-the-next-multimodal-element (textual tokens or visual embeddings) is the only one used during Emu2’s training. This unified generative pretraining technique trains models by utilizing large-scale multimodal sequences, such as text, image-text pairs, and interleaved image-text video.

The Emu2 model is generative and multimodal; it learns in a multimodal setting to predict the next element. Visual Encoder, Multimodal Modeling, and Visual Decoder are the three main parts of Emu2’s design. To prepare for autoregressive multimodal modeling, the Visual Encoder tokenizes all input images into continuous embeddings, subsequently interleaved with text tokens. The Visual Decoder turns the regressed visual embeddings into a movie or image.

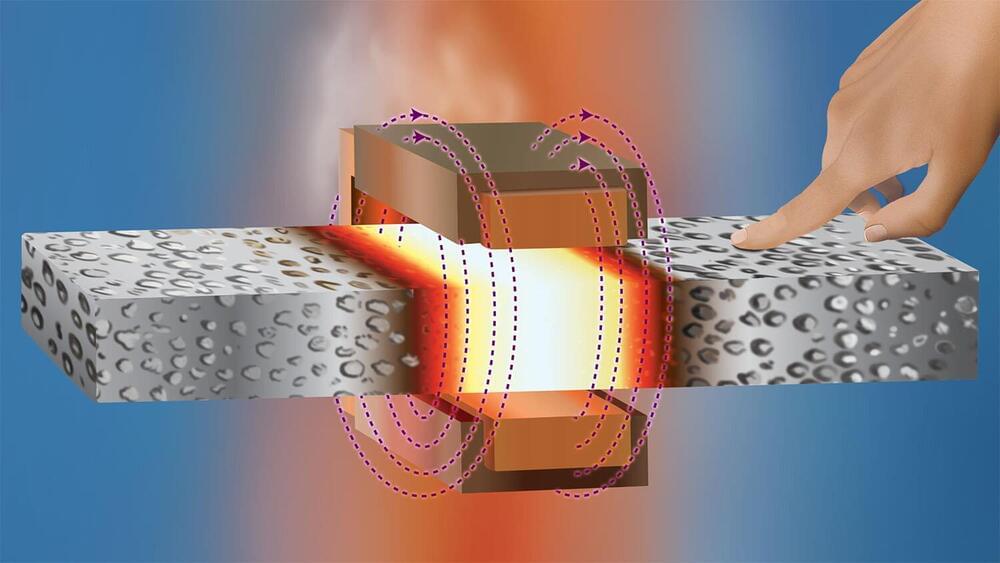

Researchers find way to weld metal foam without melting its bubbles

Researchers at North Carolina State University have now identified a welding technique that can be used to join composite metal foam (CMF) components together without impairing the properties that make CMF desirable. CMFs hold promise for a wide array of applications because the pockets of air they contain make them light, strong and effective at insulating against high temperatures.

CMFs are foams that consist of hollow, metallic spheres—made of materials such as stainless steel or titanium—embedded in a metallic matrix made of steel, titanium, aluminum or other metallic alloys. The resulting material is both lightweight and remarkably strong, with potential applications ranging from aircraft wings to vehicle armor and body armor.

In addition, CMF is better at insulating against high heat than conventional metals and alloys, such as steel. The combination of weight, strength and thermal insulation means that CMF also holds promise for use in storing and transporting nuclear material, hazardous materials, explosives and other heat-sensitive materials.

Tesla’s $1 Trillion Projection in 2024: Analysts Clash

Despite facing opposition and controversy, Tesla and Elon Musk continue to revolutionize the industry and gain support, with the company’s valuation and Musk’s outspoken personality driving outsized interest.

Questions to inspire discussion.

What challenges is Tesla facing with Cybertruck deliveries?

—Tesla is facing hindrances in Cybertruck deliveries due to battery production issues, potentially leading to missed production targets.

Turning up the Volume of Pouring Water

Experiments performed by psychologists indicate that many people can tell whether their tea is hot or cold by listening to it being poured into a mug. Pouring sounds can also contain other information about a liquid—a connection that has been thoroughly investigated for natural fluids, ranging from rain drops to ocean waves. Now Ho-Young Kim from Seoul National University, South Korea, and colleagues have studied an artificial system—a fluid jet hitting a liquid bath—revealing that the volume of the sound that is produced depends on the jet’s shape prior to impact [1]. The results indicate that sound could be used as a noninvasive probe of oxygen levels in bodies of water, says Kim.

The researchers sent a few-millimeters-diameter jet of water down a nozzle that hung above a 10-cm-diameter water-filled cylinder. Using an underwater microphone they recorded the amplitude of the sounds produced when the jet hit the surface as a function of the nozzle’s height. Using a camera, they monitored the pattern of bubbles that formed in the cylinder after jet impact and the outline of the jet, which for sufficiently high nozzles broke up into a train of droplets prior to hitting the water surface.

The team found that as the jet developed more ripples and then broke into droplets, it produced louder sounds—a consequence of the trapping of more air bubbles in the water bath. The result implies that, since thin jets break up more easily than thick ones, thin jets should splash more loudly for a given pouring height. Trying to silently serve tea by carefully pouring a thin stream of liquid may thus be unsuccessful, says Kim.

‘Golden Veil’: China makes material that disguises missile as passenger jet

A Chinese research team claims to have developed a new device called ‘Golden Veil’ that can disguise cruise missiles as commercial aircraft.

KITT The Amazing Car Of Tomorrow — A Knightrider Christmas

Let’s kick off the Holiday Season in style, shall we? Like, say, with a single few people even know exist, from a massive pop culture phenomenon of the early ’80s? YES PLEASE! This really needs no introduction. It’s KITT, the Amazing Car of Tomorrow, in full hero mode, Saving Santa from bad weather, and then making the rounds to bring joy and cheer on Christmas Morning — All told in an early ’80s rap, over an electro groove lifted from the Knight Rider theme song. Hopefully you’ve already hit play, but if you haven’t yet, HIT PLAY NOW! And if you have, then PLAY IT AGAIN! And of course, I’d like to wish you all a Verry Merry Christmas! Like it? Subscribe! Follow me at / djmikebrady I don’t own any of the rights associated with this music, I simply share so that it will be heard. #PlayingRecords #NeedleDrop #RecordCollection