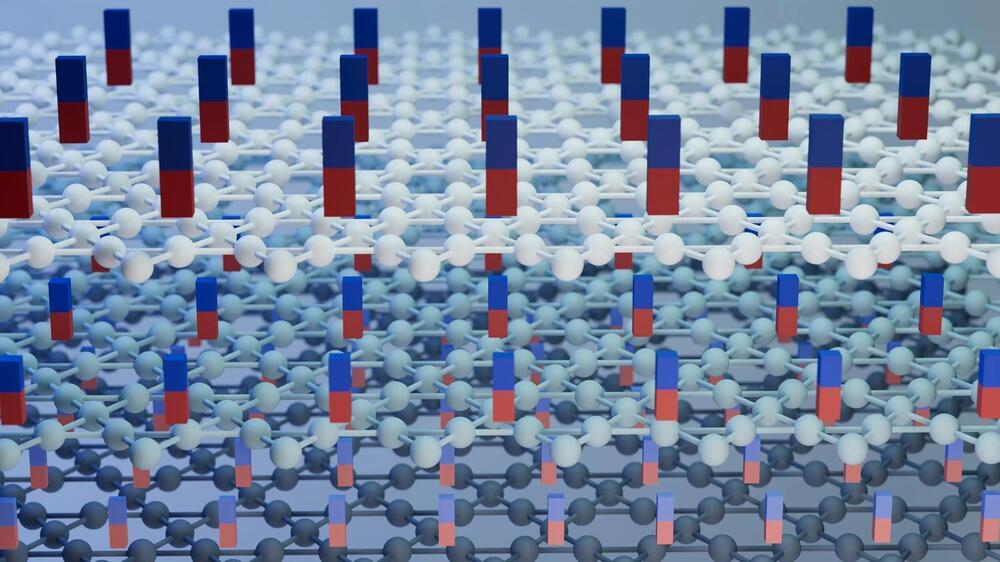

Graphene is a simple material containing only a single layer of carbon atoms, but when two sheets of it are stacked together and offset at a slight angle, this twisted bilayer material produces numerous intriguing effects, notably superconductivity.

Science can be difficult to explain to the public. In fact, any subfield of science can be difficult to explain to another scientist who studies in a different area. Explaining a theoretical science concept to high school students requires a new way of thinking altogether.

A new hydrogel semiconductor from the University of Chicago offers a groundbreaking solution for bioelectronics, blending tissue-like properties with high electronic functionality, enhancing medical device integration and effectiveness.

The perfect material for interfacing electronics with living tissue is soft, stretchable, and as water-loving as the tissue itself, making hydrogels an ideal choice. In contrast, semiconductors, the key materials for bioelectronics such as pacemakers, biosensors, and drug delivery devices, are rigid, brittle, and hydrophobic, making them impossible to dissolve in the way hydrogels have traditionally been built.

Breakthrough in Bioelectronics.

Using muon spin rotation at the Swiss Muon Source SmS, researchers at the Paul Scherrer Institute (PSI) have discovered that a quantum phenomenon known as time-reversal symmetry breaking occurs at the surface of the Kagome superconductor RbV3Sb5 at temperatures as high as 175 K. This sets a new record for the temperature at which time-reversal symmetry breaking is observed among Kagome systems.

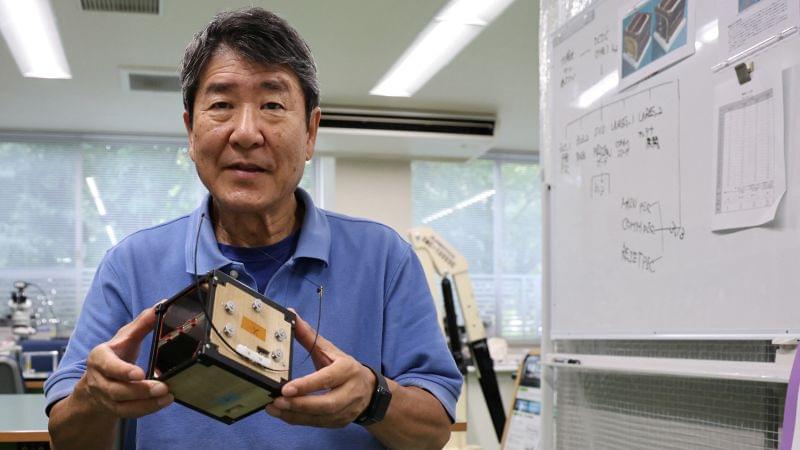

The world’s first wooden satellite, built by Japanese researchers, was launched into space on Tuesday, in an early test of using timber in lunar and Mars exploration.

LignoSat, developed by Kyoto University and homebuilder Sumitomo Forestry, will be flown to the International Space Station on a SpaceX mission, and later released into orbit about 400 kilometers (250 miles) above the Earth.

Named after the Latin word for “wood,” the palm-sized LignoSat is tasked to demonstrate the cosmic potential of the renewable material as humans explore living in space.

Old article. Simple and cheap solution.

MIT researchers have come up with a promising approach to controlling methane emissions and removing it from the air, using an inexpensive and abundant clay called zeolite.

The future of wireless technology—from charging devices to boosting communication signals—relies on the antennas that transmit electromagnetic waves becoming increasingly versatile, durable and easy to manufacture. Researchers at Drexel University and the University of British Columbia believe kirigami, the ancient Japanese art of cutting and folding paper to create intricate three-dimensional designs, could provide a model for manufacturing the next generation of antennas.

Recently published in the journal Nature Communications, research from the Drexel-UBC team showed how kirigami—a variation of origami—can transform a single sheet of acetate coated with conductive MXene ink into a flexible 3D microwave antenna whose transmission frequency can be adjusted simply by pulling or squeezing to slightly shift its shape.

The proof of concept is significant, according to the researchers, because it represents a new way to quickly and cost-effectively manufacture an antenna by simply coating aqueous MXene ink onto a clear elastic polymer substrate material.