Archive for the ‘materials’ category: Page 278

Jul 19, 2016

Implantable Artificial Kidney

Posted by Shailesh Prasad in categories: biotech/medical, materials

Jul 18, 2016

New light harvesting potentials

Posted by Karen Hurst in categories: materials, quantum physics

By narrowing the bandgap of titania and graphene quantum dots.

Researchers have found a method of harvesting light.

Griffith University researchers have discovered significant new potentials for light harvesting through narrowing the bandgap of titania and graphene quantum dots.

Jul 14, 2016

New light harvesting potentials uncovered

Posted by Karen Hurst in categories: materials, quantum physics

New options in harvesting light.

Significant new potentials for light harvesting through narrowing the bandgap of titania and graphene quantum dots have been uncovered by scientists.

Jul 12, 2016

No Big Bang –“Our Universe Was Formed From an Older Collapsing Universe”

Posted by Karen Hurst in categories: cosmology, materials

A new study of the early universe reveals how it could have been formed from an older collapsing universe, rather than being brand new. The universe is currently expanding and it is a common theory that this is the result of the ‘Big Bang’ – the universe bursting into existence from a point of infinitely dense and hot material.

Jul 12, 2016

High-tech fillings could actually repair your teeth

Posted by Karen Hurst in categories: biotech/medical, materials

These award-winning new materials for dental fillings could help repair and regenerate parts of your damaged teeth.

Jul 11, 2016

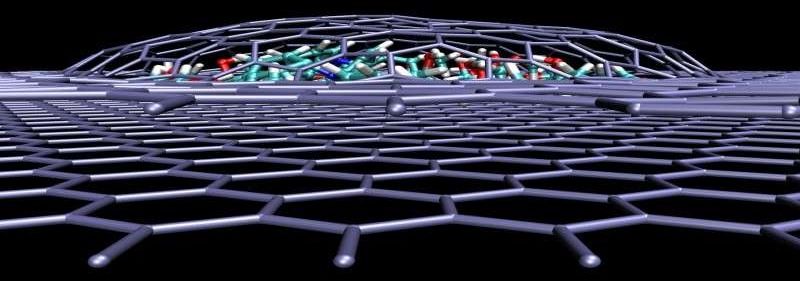

Mussels inspire scientists to attach biologically active molecule to titanium surface

Posted by Karen Hurst in categories: biotech/medical, materials

Very cool; another example where nature inspires others. Einstein was inspired often by nature and its environment.

Titanium is used medically in applications such as artificial joints and dental implants. While it is strong and is not harmful to tissues, the metal lacks some of the beneficial biological properties of natural tissues such as bones and natural teeth. Now, based on insights from mussels—which are able to attach themselves very tightly to even metallic surfaces due to special proteins found in their byssal threads—scientists from RIKEN have successfully attached a biologically active molecule to a titanium surface, paving the way for implants that can be more biologically beneficial.

The work began from earlier discoveries that mussels can attach to smooth surfaces so effectively thanks to a protein, L-DOPA, which is known to be able to bind very strongly to smooth surfaces such as rocks, ceramics, or metals. Interestingly, the same protein functions in humans as a precursor to dopamine, and is used as a treatment for Parkinson’s disease.

Jul 8, 2016

Tiny Hydraulic ‘Nano-Press’ Crushes Things Out of This Dimension

Posted by Karen Hurst in categories: materials, nanotechnology

Jul 8, 2016

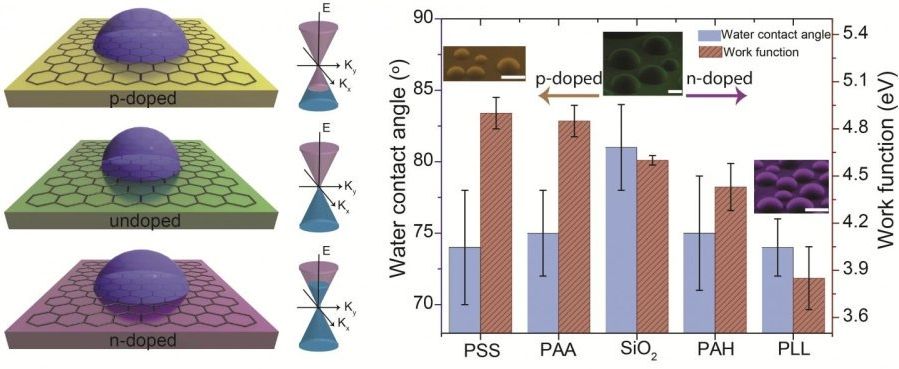

Tunable wetting and adhesion of graphene demonstrated

Posted by Karen Hurst in categories: engineering, materials

Nice.

“Our study suggests for the first time that the doping-induced modulation of the charge carrier density in graphene influences its wettability and adhesion,” explained SungWoo Nam, an assistant professor in the Department of Mechanical Science and Engineering at Illinois. “This work investigates this new doping-induced tunable wetting phenomena which is unique to graphene and potentially other 2D materials in complementary theoretical and experimental investigations.”

Graphene, being optically transparent and possessing superior electrical and mechanical properties, can revolutionize the fields of surface coatings and electrowetting displays, according to the researchers. A material’s wettability (i.e. interaction with water) is typically constant in the absence of external influence and are classified as either water-loving (hydrophilic) or water-repelling (hydrophobic; water beads up on the surface). Depending on the specific application, a choice between either hydrophobic or hydrophilic material is required. For electrowetting displays, for example, the hydrophilic characteristics of display material is enhanced with the help of a constant externally impressed electric current.

Continue reading “Tunable wetting and adhesion of graphene demonstrated” »

Jul 6, 2016

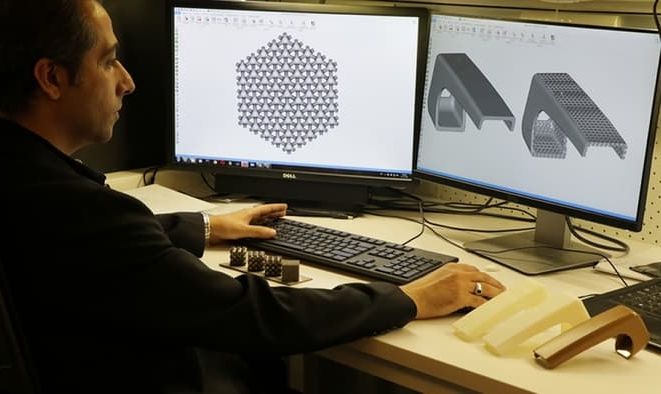

Super-strong and airy 3D-printed supermaterials inch closer to reality

Posted by Karen Hurst in categories: 3D printing, materials

Researchers at the Masdar Institute are creating 3D printed high performance materials with custom-designed mechanical, thermal and electrical properties by manipulating the materials’ internal structures.