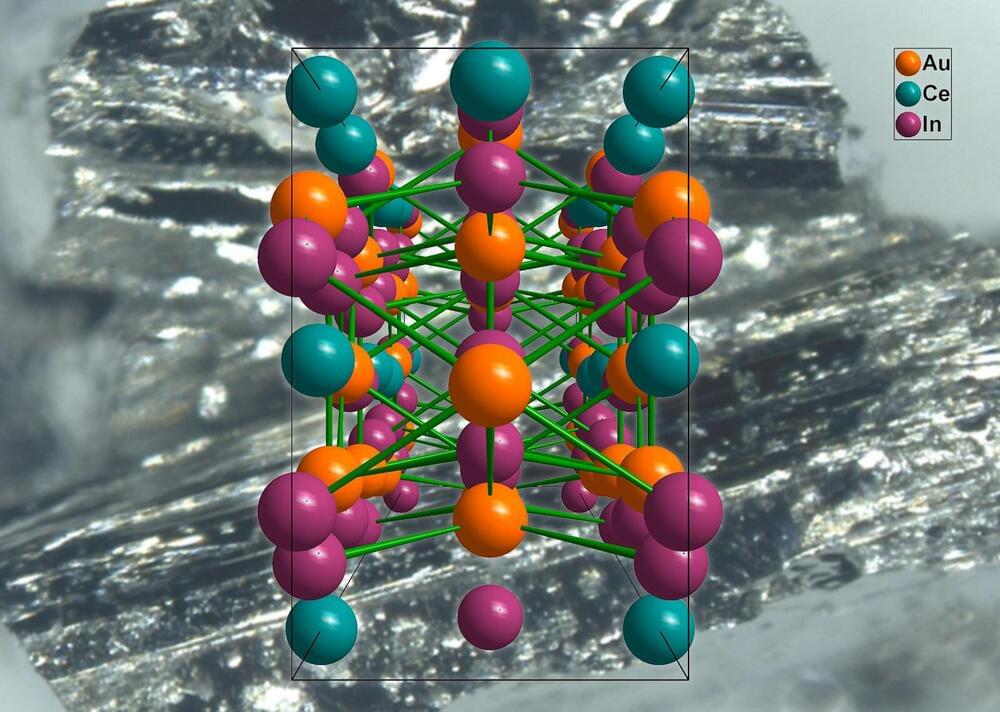

How do you find novel materials with very specific properties—for example, special electronic properties which are needed for quantum computers? This is usually a very complicated task: various compounds are created, in which potentially promising atoms are arranged in certain crystal structures, and then the material is examined, for example in the low-temperature laboratory of TU Wien.

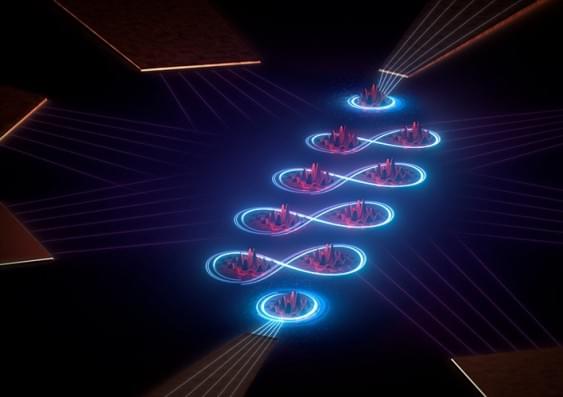

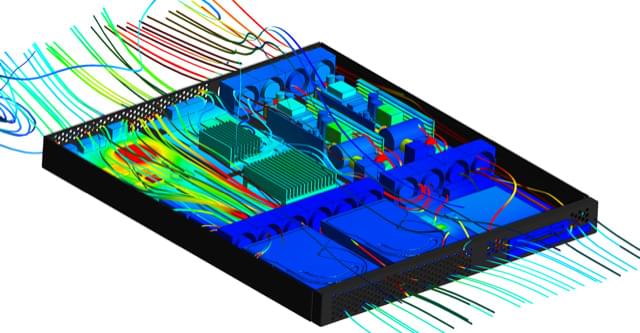

Now, a cooperation between Rice University (Texas), TU Wien and other international research institutions has succeeded in tracking down suitable materials on the computer. New theoretical methods are used to identify particularly promising candidates from the vast number of possible materials. Measurements at TU Wien have shown the materials do indeed have the required properties and the method works. This is an important step forward for research on quantum materials. The results have now been published in the journal Nature Physics.