When we form a new memory, the brain undergoes physical and functional changes known collectively as a “memory trace.” A memory trace represents the specific patterns of activity and structural modifications of neurons that occur when a memory is formed and later recalled.

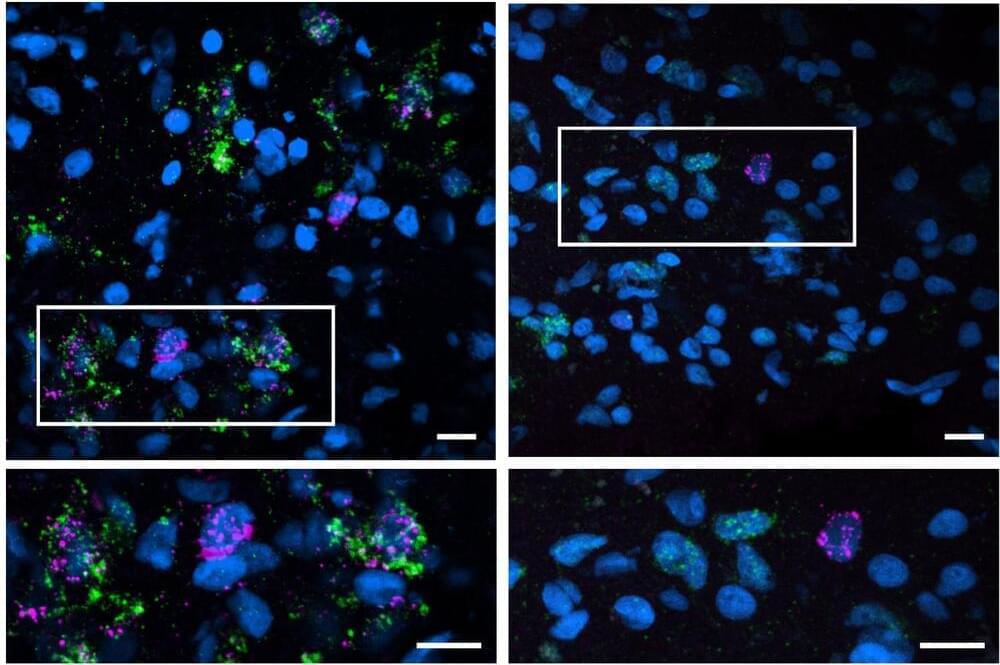

But how does the brain “decide” which neurons will be involved in a memory trace? Studies have suggested that the inherent excitability of neurons plays a role, but the currently accepted view of learning has neglected to look inside the command center of the neuron itself, its nucleus. In the nucleus, there seems to be another dimension altogether that has gone unexplored: epigenetics.

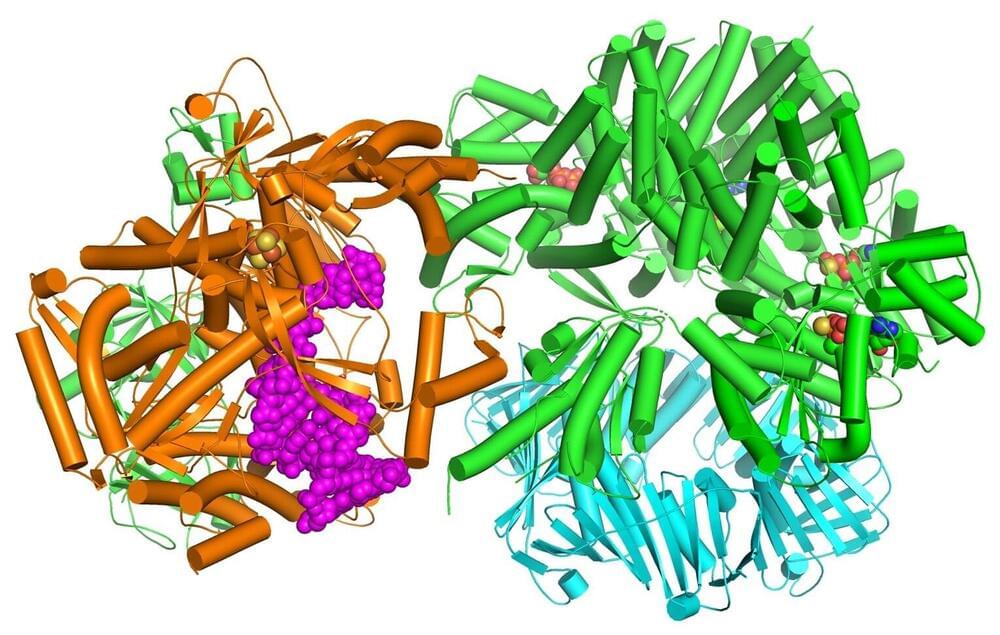

Inside every cell of a given living organism, the genetic material encoded by the DNA is the same, yet the various cell types that make up the body, like skin cells, kidney cells, or nerve cells each express a different set of genes. Epigenetics is the mechanism of how cells control such gene activity without changing the DNA sequence.