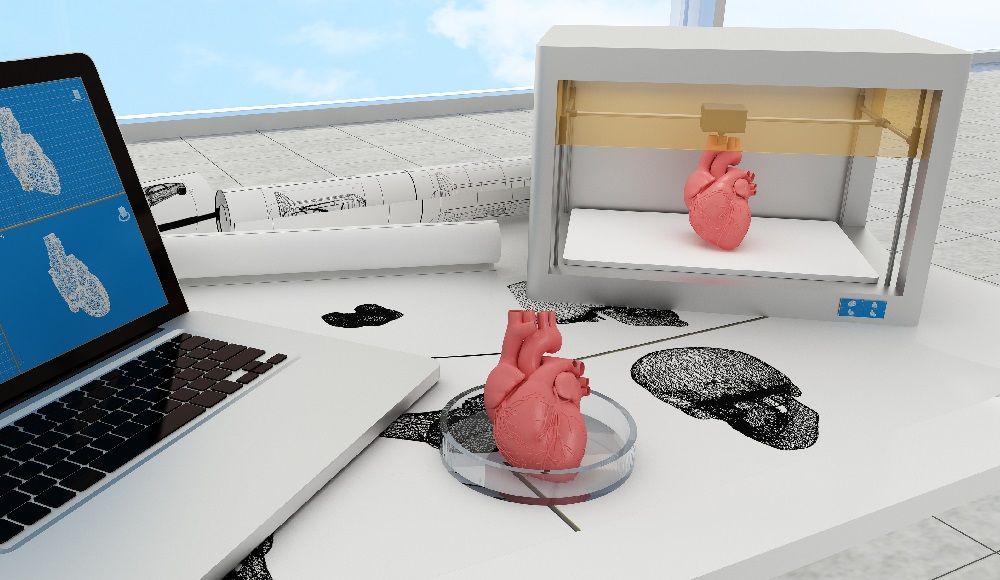

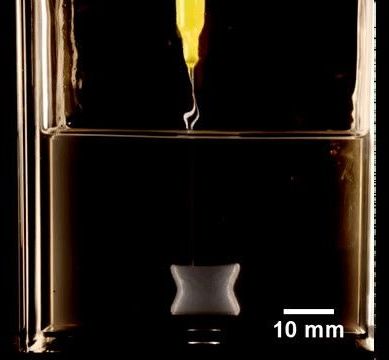

Erik Gatenholm is Co-Founder and CEO here at CELLINK. In 2017, he founded CELLINK to revolutionize the way that we conduct medical research worldwide. He led a workshop at the C2 Montreal conference called “Need a tissue, Bioprinting is the next Medical Revolution”

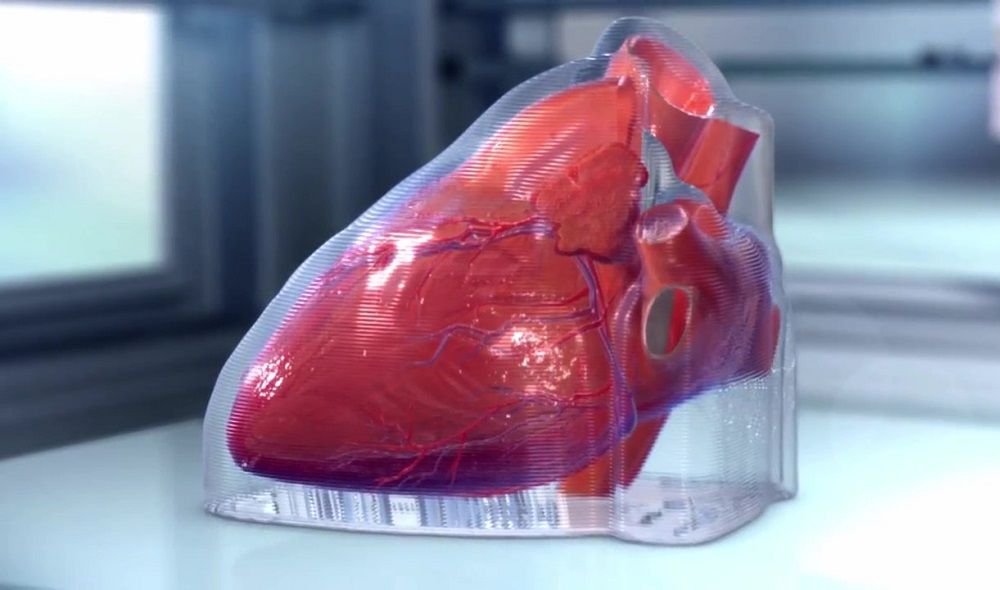

At C2 Montreal – There was a presentation on bioprinting and Cellink technology. Then there was an activity where people in groups looked at a sample of bioprinted tissue and people worked on exercises of what people thought was possible or preposterous in the future.

There was a forecast of increased tissue engineering enhanced plastic surgery.