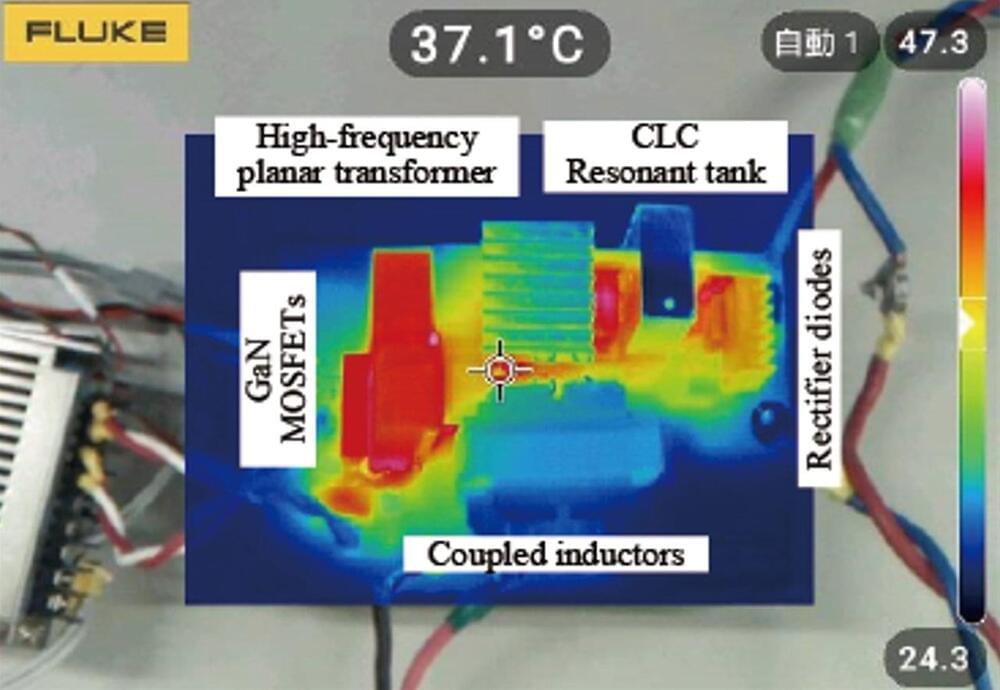

A new electrical power converter design developed by Kobe University offers significantly improved efficiency at a reduced cost and lower maintenance. This direct current voltage boost converter is set to make a substantial impact on the development of electric and electronic components in various sectors, including power generation, healthcare, mobility, and information technology.

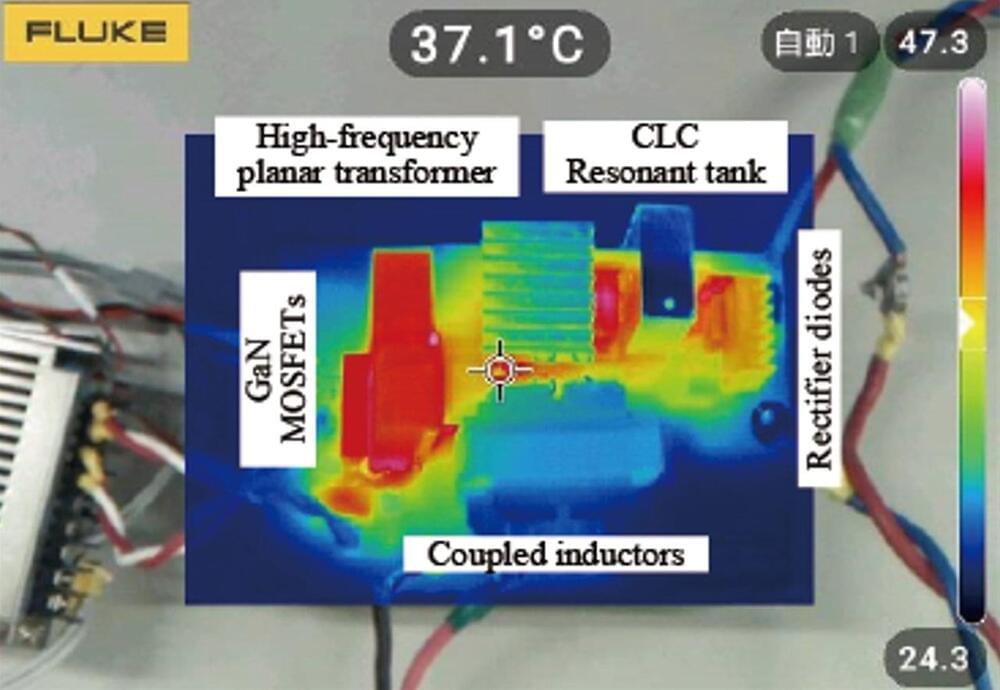

Devices that harvest energy from sunlight or vibrations, or power medical devices or hydrogen-fueled cars have one key component in common. This so-called “boost converter” converts low-voltage direct current input into high-voltage direct current output. Because it is such a ubiquitous and key component, it is desirable that it uses as few parts as possible for reduced maintenance and cost and at the same time that it operates at the highest possible efficiency without generating electromagnetic noise or heat. The main working principle of boost converters is to quickly change between two states in a circuit, one that stores energy and another that releases it. The faster the switching is, the smaller the components can be and therefore the whole device can be downsized. However, this also increases the electromagnetic noise and heat production, which deteriorates the performance of the power converter.

The team of Kobe University power electronics researcher Mishima Tomokazu made significant progress in developing a new direct current power conversion circuit. They managed to combine high-frequency switching (about 10 times higher than before) with a technique that reduces electromagnetic noise and power losses due to heat dissipation, called “soft switching,” while also reducing the number of components and, therefore, keeping cost and complexity low.