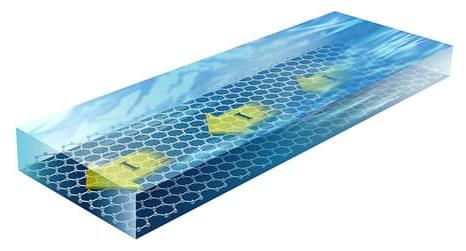

Researchers have developed a proof of concept technology that could pave the way for next-generation displays beyond current LCDs and LEDs, enabling screens and electronic devices to become thinner, offer higher resolution and be much more energy efficient.

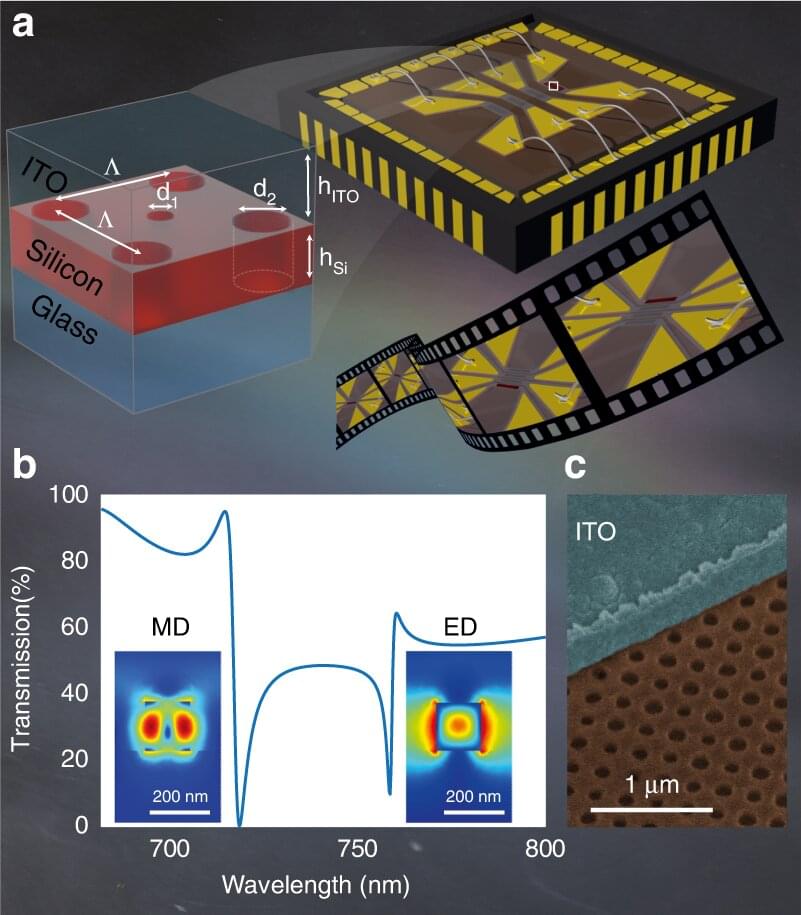

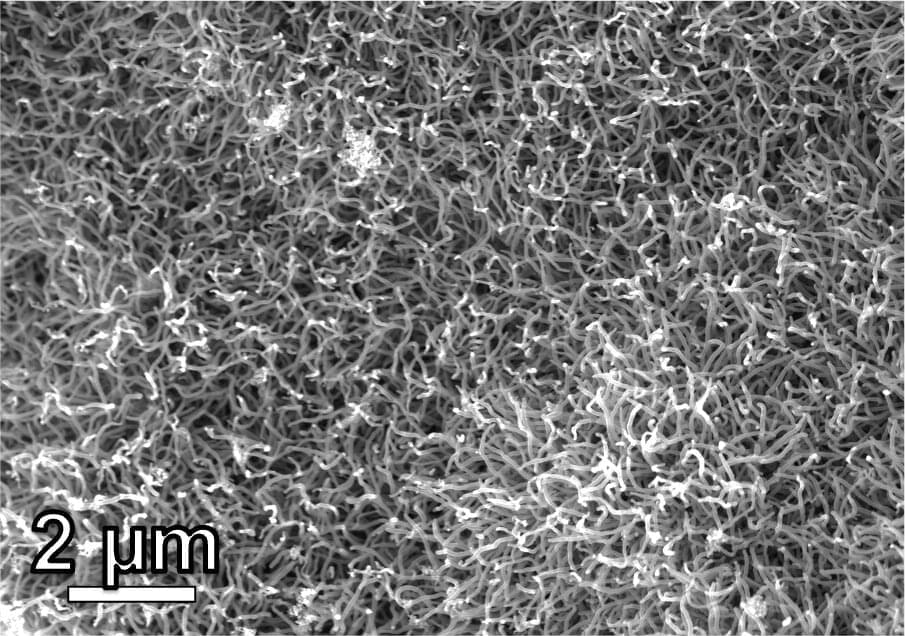

A team at Nottingham Trent University, the Australian National University and the University of New South Wales Canberra in Australia has engineered electrically tunable arrays of nanoparticles called “metasurfaces,” which can offer significant benefits over current liquid crystal displays.

Today’s display market offers a large range of choices, each with its pros and cons. However factors including production costs, lifespan and energy consumption have kept liquid crystal technology the most dominant and popular technology for screens such as TV sets and monitors.