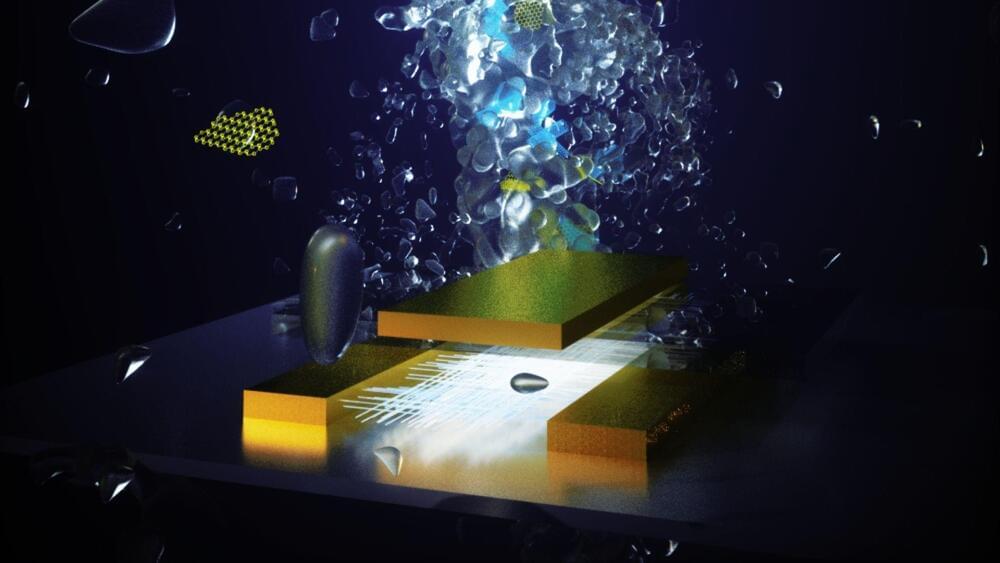

The team developed a cyclical process in which the device is rinsed with water, dried in relatively low heat, and printed on again.

In the electronics industry, placing several layers of components on top of each other to develop complex devices is no easy task. And with printed electronics, the task is more complicated.

“If you’re making a peanut butter and jelly sandwich, one layer on either slice of bread is easy,” Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke, said in a statement. “But if you put the jelly down first and then try to spread peanut butter on top of it, forget it, the jelly won’t stay put and will intermix with the peanut butter.

The current electronics fabrication technology relies on hazardous chemicals and toxic gases. The entire industry has also been flagged for attention by the US Environmental Protection Agency.

Comments are closed.