MIT researchers have developed a method for 3D printing materials with tunable mechanical properties, that sense how they are moving and interacting with the environment. The researchers create these sensing structures using just one material and a single run on a 3D printer.

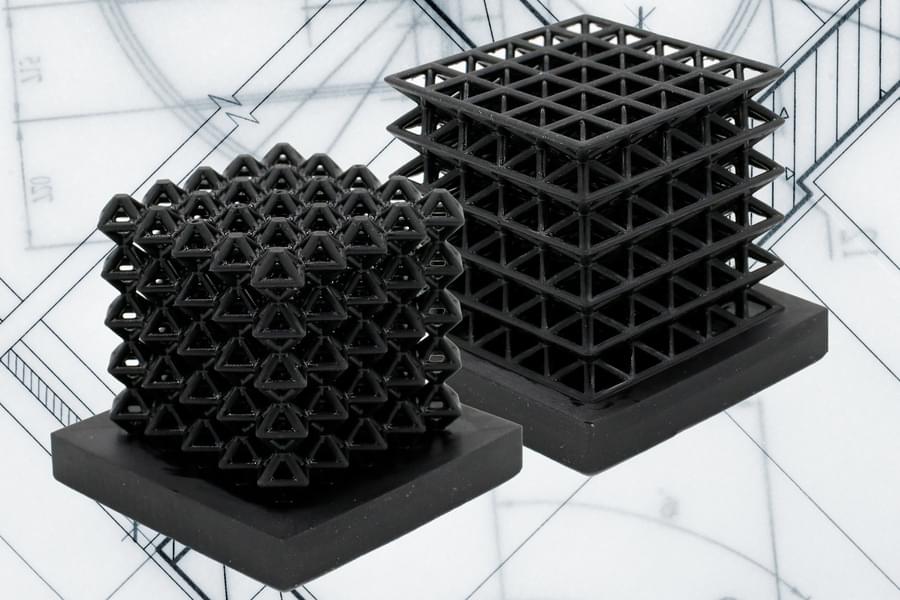

To accomplish this, the researchers began with 3D-printed lattice materials and incorporated networks of air-filled channels into the structure during the printing process. By measuring how the pressure changes within these channels when the structure is squeezed, bent, or stretched, engineers can receive feedback on how the material is moving.

The method opens opportunities for embedding sensors within architected materials, a class of materials whose mechanical properties are programmed through form and composition. Controlling the geometry of features in architected materials alters their mechanical properties, such as stiffness or toughness. For instance, in cellular structures like the lattices the researchers print, a denser network of cells makes a stiffer structure.

Comments are closed.