One promising solution to plastic pollution is mycelium or mushroom packaging. It is made of 2 ingredients: mushrooms and hemp. Mycelium is the underground network of very durable, thread-like filaments called hyphae. It is mixed with agricultural waste like wood chips, oat hulls, cotton burrs or hemp hurds.

Link to my Patreon page: https://www.patreon.com/Belinda_Carr.

Chapters.

0:00 Introduction.

1:00 How its made.

2:43 Products.

4:32 Advantages.

5:30 Disadvantages.

6:19 Myths.

7:12 Conclusion.

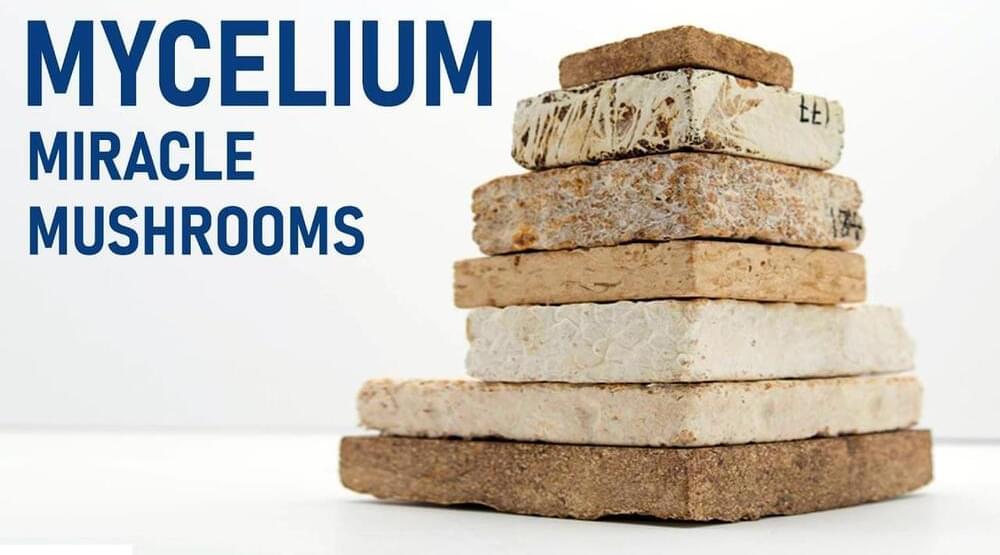

One of the largest mushroom packaging manufacturers in the world is Ecovative Design, a New York based biotech company founded in 2006. They sent me these samples of their product. Their manufacturing process is pretty straight forward.

Their designers create a 3D CAD model of custom packaging.

A CNC machine routes the design into MDF.

Plastic trays are thermoformed around the MDF pieces.

The tray is filled with their proprietary hemp hurd and mycelium blend.

It is allowed to grow for 4 days in a controlled environment with regulated temperatures, airflow, CO2 and humidity levels.

It is popped out of tray and allowed to continue growing for 2 more days to create a velvety layer of overgrowth.

The packaging is then heat treated to dry out, kill spores and stop the growth process.

This material can last for 30 years in dry, temperature controlled indoor environments. It is also 100% biodegradable and a nutrient for soils and plants. When broken down into 1 cubic centimeter pieces, it will compost in just 45 days. In the ocean, it will compost in 180 days.

Comments are closed.