Nice.

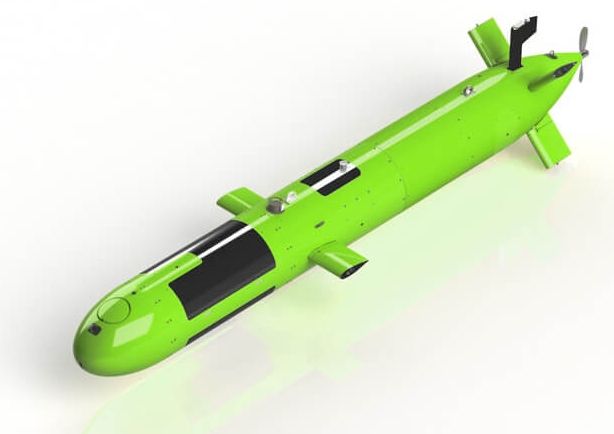

Submarine manufacturer saves major time and cost by 3D Printing a titanium Variable Ballast tank with EBM technology from Sciaky.

The production of an Arctic Explorer submarine was nearly scuppered after the supplier of a component went out of business. To find a solution, however, International Submarine Engineering (ISE) didn’t have to dive too deep. They turned instead to additive manufacturing.

ISE had originally planned to produce the titanium Variable Ballast (VB) tank with traditional manufacturing methods. Their key supplier was an overseas titanium forging facility that previously produced propellant tanks for the Russian space program. But then the supplier went bankrupt.

Comments are closed.