by Brian Krassenstein — 3Dprint.com

The ability to 3D print objects of all shapes, and many sizes, has enabled individuals to take at least some control of their lives away from the large manufacturers and corporations out there. We can now become the makers of what we consumer. 3D printing has been touted as a way to cut back on waste. Additive manufacturing is clearly a much better fabrication method than that of subtractive manufacturing. These new processes are certainly saving materials for the large manufacturers out there who may be printing in metals, or other materials instead of using milling techniques. For those of us who use ordinary FDM-based desktop 3D printers to make trinkets and little doo-dads, let’s be honest, we are probably causing more plastic waste than we were prior to purchasing these machines. How many 3D prints have you had which have failed and you simply end up throwing away? Half of the stuff you print, you likely would never have purchased anyway, right?

Common 3D Printers are slow, taking an hour or more to produce common relatively small products. The finish is not smooth and tolerance is difficult to control. So machined subtractive processes are still the viable choice for doing mass production.

Even in our school, fabrication MUST be done “with purpose”.

There are some parts with internal features where additive processes are the best solution; though most often, not the only solution.

For our school, we use Commercial Off The Shelf (COTS) products, supplemented by 3D printing for small fragile mounting fixtures and CNC for anything structural that is not available in COTS. There are exceptions, such as social media. 3D printing can comparatively do one-off’s much faster than CNC in-general. Exceptions again related to laminant materials in which laser-cutters are far faster and easier to fabricate with than 3D printers in most cases.

Many things must be considered in design for manufacturing. Why there are degrees with similar naming.

For the home enthusiast, where nothing is sold, a 3D printer is just a fad waiting to be sold on Craigslist.

For a home enthusiast’s children, a 3D printer may be an educational tool to inspire greater aspirations.

For a business owner, a 3D printer can produce sales media not affordable otherwise.

For an engineer, a 3D printer can be used to check clearances, operations, and tolerances at a fraction of the cost of producing the prototypes in actual 3D operations.

For the artist, a 3D printer can mean expressing themselves in previously impossible media. Artwork with detailed internal features not previously practical to consider. Like doing a cross section of a 3D fractal; see YouTube.

The waste is recyclable, and is a valid consideration.

For those wanting FREE software and tutorials to learn and build actual .STP (aka STEP files) that the 3D printers need to produce the machine operations.

Tutorials are available on YouTube and other web resources.

Download FREE Inventor Software

http://www.autodesk.com/education/free-software/inventor-professional

See YouTube online tutorials

Google Search: autodesk inventor youtube tutorials

More important than the waste produced, is the development of people’s interests in STEM education, and learning to think further than the end of their spear. Project-based education trains the brain to think about consequences.

James Dunn

Several issues need to be addressed.

An ideal 3D printer suitable for home, what uses should have? I could print with it spare parts of home appliances. As a creative person, I would dare to create my own artworks, or even shoes, certain dresses, foods, solar panels and much more. There is plenty of space for creating useful or simply pleasent objects. No need to go for shopping any more!

But low cost and flexibility do not exist yet sufficiently. I guess this is the reason self-made home 3D objects are presently made mostly by enthusiasts and finally they result useless.

We need a technological exponential improvement able to generate a leap in the range of products and in the quality. I am thinking to not only to low cost, but also to multipurpose 3 D printers, using few types of standardized materials, able to improve the characteristcs of the final products via nanototech printing. Virtually anything useful for every day life could be made. I would like them to print also chemicals and pharmaceuticals, and more generally the health products the emerging Watsons and internet of things are going to tell when you need in real time.

Meanwhile I guess 3D printing centers, able to produce almost everything with state of the art 3D machines, will become more and more common. Printers working 24 hours a day, able to produce sofisicated products with great economies os scale. You will order directly the final product via internet from a catalog or send your own printing program or you will hire machine time if you like. You will obtain many of the same products now available in a superstores or better much much more, even objects of the past or with unbelievable characteristics, of course at a fraction of today’s cost.

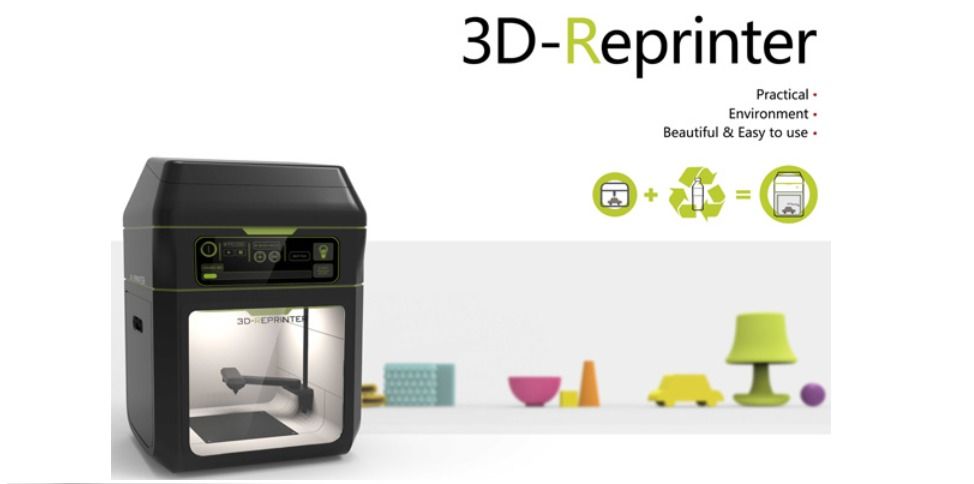

No waste any more. When you want to get rid of a 3D product, just mill it and reprint a new one or alternatively send it to a 3D center for reprocessing.

Keep in mind that 3D printer output now includes dyes, electronic components in the form of shaped metallic powder and other added materials that would have to be removed prior to reuse — and some of these materials are not environmentally- or biologically-friendly. This would require (at least in the near term) a processing center, as Marco mentioned in his comment.