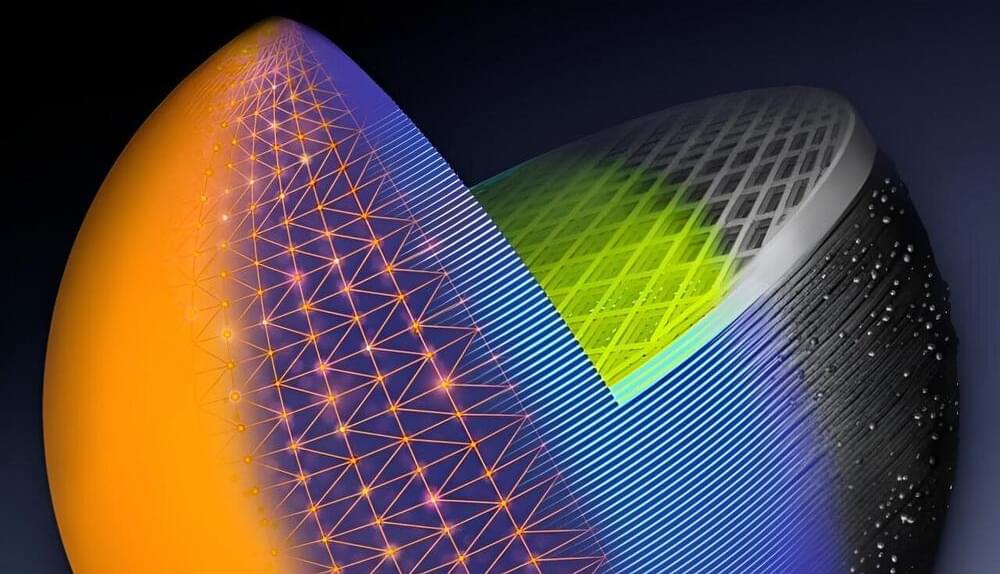

Researchers at the Department of Energy’s Oak Ridge National Laboratory have developed the first additive manufacturing slicing computer application to simultaneously speed and simplify digital conversion of accurate, large-format three-dimensional parts in a factory production setting.

The technology, known as Slicer 2, can help widen the use of 3D printing for larger objects made from metallic and composite materials. Objects the size of a house and beyond are possible, such as land and aquatic vehicles and aerospace applications that include parts for reusable space vehicles.

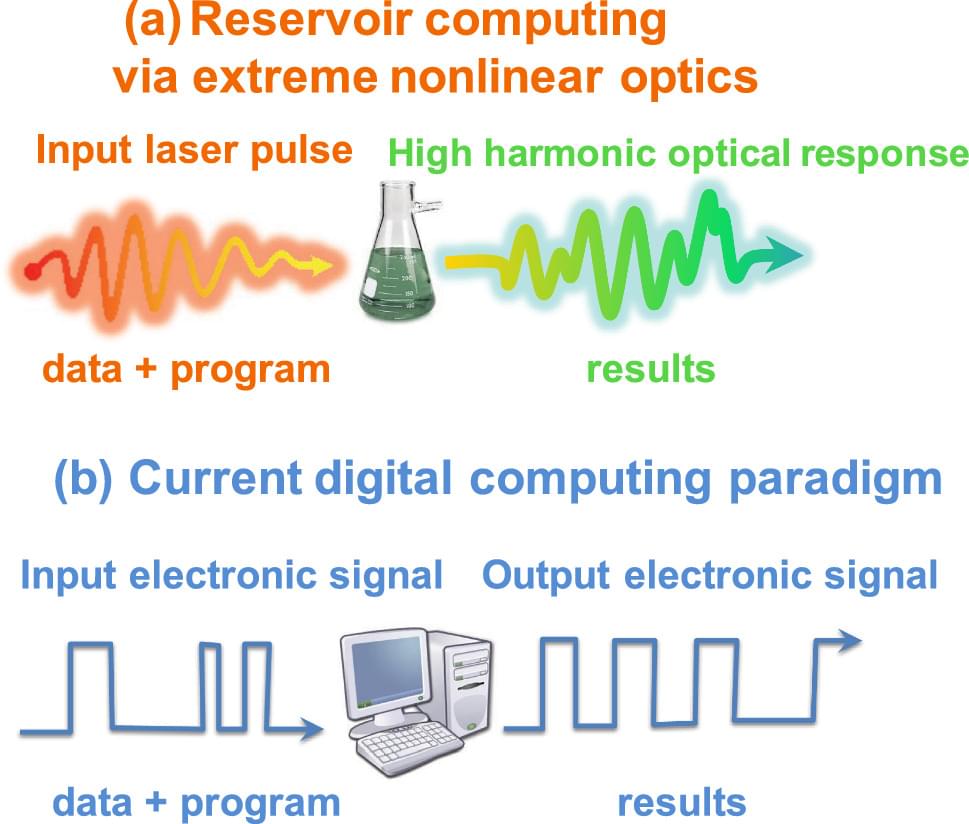

Slicing software converts a computer-aided design, or CAD, digital model into a series of two-dimensional layers called slices. It calculates print parameters for each slice, such as printhead path and speed, and saves the information in numerically controlled computer language. The computer file contains instructions for a 3D printer to create a precise 3D version of the image.