Apr 27, 2023

The Efficiency of Tandem Molecular Machines

Posted by Saúl Morales Rodriguéz in category: nanotechnology

Machines that consist of two coupled biomolecules trade thermodynamic efficiency for operating speed.

Machines that consist of two coupled biomolecules trade thermodynamic efficiency for operating speed.

A new gel-based treatment for glioblastoma—a highly aggressive form of brain cancer—has shown to be 100% effective at preventing recurrence in mice. Researchers hope the therapy will translate well into human physiology, where it could help resolve tens of thousands of cancer diagnoses every year.

Glioblastoma manifests as a tumor growing on the brain or spinal cord. While many glioblastoma patients have the tumor surgically removed, the mass often returns, even in cases involving post-surgical radiation or chemotherapy. The disease is so persistent that the average patient lives only 12 to 16 months after diagnosis, making glioblastoma one of the most lethal forms of cancer currently understood.

Continue reading “New Therapy Found to Prevent Aggressive Brain Cancer Recurrence in Mice” »

Nagoya University.

Nagoya University, sometimes abbreviated as NU, is a Japanese national research university located in Chikusa-ku, Nagoya. It was the seventh Imperial University in Japan, one of the first five Designated National University and selected as a Top Type university of Top Global University Project by the Japanese government. It is one of the highest ranked higher education institutions in Japan.

Scientists have demonstrated that nanowire networks can exhibit short-and long-term memory, similar to the human brain. These networks, comprised of highly conductive silver wires covered in plastic and arranged in a mesh-like pattern, mimic the physical structure of the human brain. The team successfully tested the nanowire network’s memory capabilities using a task similar to human psychology experiments. This breakthrough in nanotechnology suggests that non-biological hardware systems could potentially replicate brain-like learning and memory, and has numerous real-world applications, such as improving robotics and sensor devices in unpredictable environments.

In a groundbreaking study, an international team has shown that nanowire networks can mimic the short-and long-term memory functions of the human brain. This breakthrough paves the way for replicating brain-like learning and memory in non-biological systems, with potential applications in robotics and sensor devices.

Continue reading “Neural Nanotechnology: Nanowire Networks Learn and Remember Like a Human Brain” »

Sometimes to make big breakthroughs, you have to start very small.

One way that scientists can get the most out of certain quantum materials is by fabricating nanoscale structures that generate new properties at the material’s surfaces and edges. Cornell researchers used the relatively straightforward process of thermomechanical nanomolding to create single-crystalline nanowires that can enable metastable phases that would otherwise be difficult to achieve with conventional methods.

“We’re really interested in this synthesis method of nanomolding because it allows us to make many different kinds of materials into nanoscale quickly and easily, yet with some of the control that other nanomaterial synthesis methods lack, particularly control over the morphology and the size,” said Judy Cha, professor of materials science and engineering in Cornell Engineering, who led the project.

A study reflects on how these plastic particles can increase the risk of neuroinflammation and neurodegeneration.

We have known for a while that microplastics are in our bloodstreams, making their way into our bodies through daily consumables like milk and meat. The foreign presence of micro and nano-plastic particles (MNPs) in our bodies is dangerous for obvious reasons, and they can potentially reach remote locations and penetrate living cells.

In a scary confirmation of this potentiality, a new study has found that polystyrene, a widely-used plastic found in food packaging, could be detected in the brain just two hours after ingestion.

Over the past year or so, generative AI models such as ChatGPT and DALL-E have made it possible to produce vast quantities of apparently human-like, high-quality creative content from a simple series of prompts.

Though highly capable – far outperforming humans in big-data pattern recognition tasks in particular – current AI systems are not intelligent in the same way we are. AI systems aren’t structured like our brains and don’t learn the same way.

Continue reading “Networks of Silver Nanowires Appear to Learn And Remember Like The Human Brain” »

An international team led by scientists at the University of Sydney has demonstrated nanowire networks can exhibit both short-and long-term memory like the human brain.

The research has been published today in the journal Science Advances (“Neuromorphic learning, working memory, and metaplasticity in nanowire networks”), led by Dr Alon Loeffler, who received his PhD in the School of Physics, with collaborators in Japan.

Photograph of nanowire network (left), network’s pathways changing and strengthening (right). (Image: Alon Loeffler)

Cameras for machine vision and robotics are essentially bionic devices mimicking human eyes. These applications require advanced color imaging systems to possess a number of attributes such as high resolution, large FoV, compact design, light-weight and low energy consumption, etc1. Conventional imaging systems based on CCD/CMOS image sensors suffer from relatively low FoV, bulkiness, high complexity, and power consumption issues, especially with mechanically tunable optics. Recently, spherical bionic eyes with curved image sensor retinas have triggered enormous research interest1,2,3,4,5,6,7. This type of devices possess several appealing features such as simplified lens design, low image aberration, wide FoV, and appearance similar to that of the biological eyes rendering them suitable for humanoid robots8,9,10,11,12,13. However, the existing spherical bionic eyes with curved retinas typically only have fixed lens and can only acquire mono color images. Fixed lenses cannot image objects with varying distances. On the other hand, conventional color imaging function of CCD/CMOS image sensors are achieved by using color filter arrays, which add complexity to the device fabrication and cause optical loss14,15,16,17,18,19. Typical absorptive organic dye filters suffer from poor UV and high-temperature stabilities, and plasmonic color filters suffer from low transmission20,21,22. And it is even more challenging to fabricate color filter arrays on hemispherical geometry where most traditional microelectronic fabrication methods are not applicable.

Herein, we demonstrate a novel bionic eye design that possesses adaptive optics and a hemispherical nanowire array retina with filter-free color imaging and neuromorphic preprocessing abilities. The primary optical sensing function of the artificial retina is realized by using a hemispherical all-inorganic CsPbI3 nanowire array that can produce photocurrent without external bias leading to a self-powered working mode. Intriguingly, an electrolyte-assisted color-dependent bidirectional synaptic photo-response is discovered in a well-engineered hybrid nanostructure. Inspired by the vertical alignment of a color-sensitive cone cell and following neurons, the device structure vertically integrates a SnO2/NiO double-shell nanotube filled with ionic liquid in the core on top of a CsPbI3/NiO core-shell nanowire. It is found that the positive surrounding gate effect of NiO due to photo hole injection can be partially or fully balanced by electrolyte under shorter (blue) or longer (green and red) wavelength illuminations, respectively. Thus, the device can yield either positive or negative photocurrent under shorter or longer wavelength illumination, respectively. The carriers can be accumulated in SnO2/NiO structure, giving rise to the bidirectional synaptic photo-response. This color-sensitive bidirectional photo-response instills a unique filter-free color imaging function to the retina. The synaptic behavior-based neuromorphic preprocessing ability, along with the self-powered feature, effectively reduce the energy consumption of the system23,24,25,26,27,28. Moreover, the color selectivity of each pixel can be tuned by a small external bias to detect more accurate color information. We demonstrate that the device can reconstruct color images with high fidelity for convolutional neural network (CNN) classifications. In addition, our bionic eye integrates adaptive optics in the device, by integrating an artificial crystalline lens and an electronic iris based on liquid crystals. The artificial crystalline lens can switch focal length to detect objects from different distances, and the electronic iris can control the amount of light reaching the retina which enhances the dynamic range. Both of the optical components can be easily tuned by the electric field, which are fast, compact, and much more energy efficient compared to the conventional mechanically controlled optics reported hitherto. (Supplementary Table 1 compares our system with some commercial zoom lenses.) The combination of all these unique features makes the bionic eye structurally and functionally equivalent to its biological counterpart.

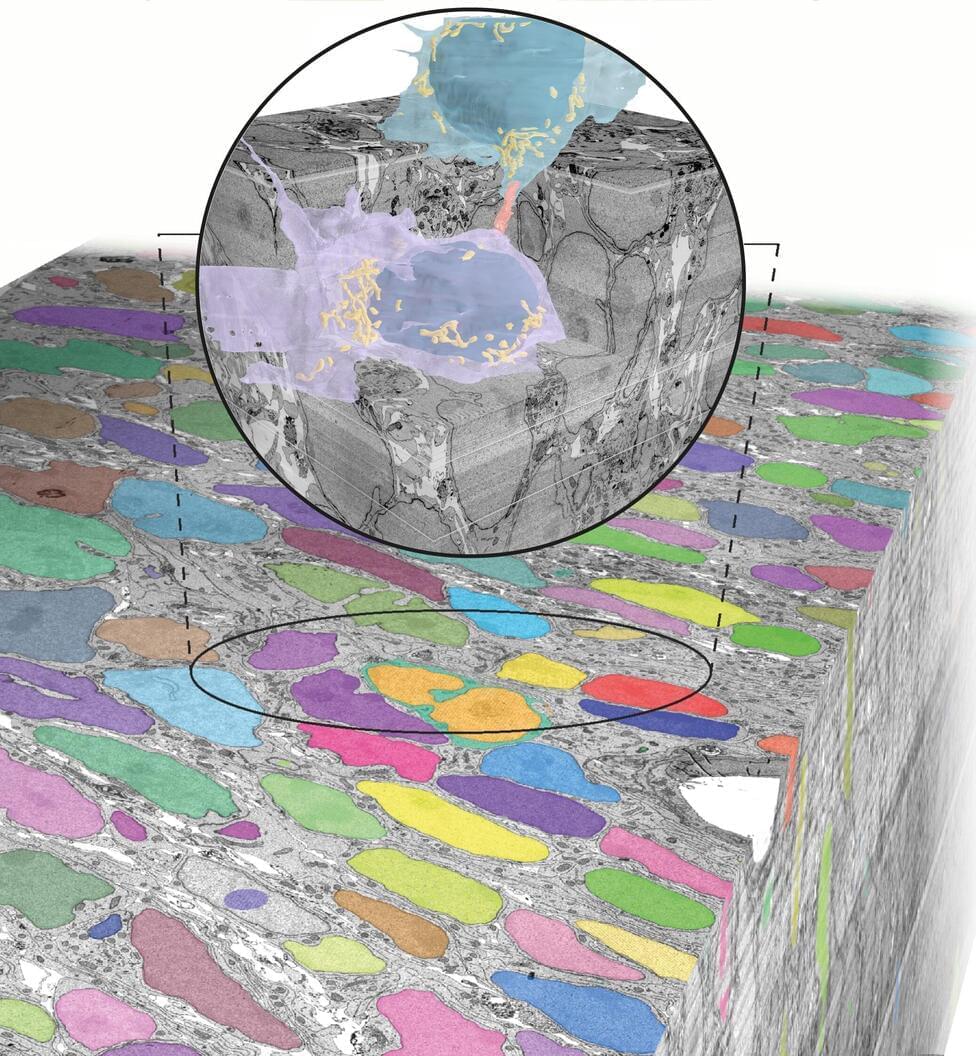

Over a hundred years after the discovery of the neuron by neuroanatomist Santiago Ramón y Cajal, scientists continue to deepen their knowledge of the brain and its development.

In a publication in Science Advances on April 5, a team from the Institut Pasteur and the CNRS, in collaboration with Harvard University, revealed novel insights into how cells in the outer layers of the brain interact immediately after birth during formation of the cerebellum, the brain region towards the back of the skull.

Continue reading “Identification of tunnels connecting neurons in the developing brain” »